Other

“In this project, I’d like to share how to build a 2-axis thermocol/ polystyrene cutting CNC machine with its frame and supports made of electrical wire casing/duct and 3D printed parts. Basically it is a thermocol cutting tool …

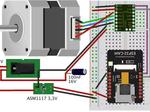

“In this project, we’ll explore how to create a high-performance stepper motor driver circuit using the TMC2209. Circuit Connection Connect the TMC2209 as follows: 1. Power Supply Connections: - Connect the VBB/VCC pin to the positive terminal of the …

“This is another one of my clock projects this time inspired by marble clocks. However, not wanting to replicate an existing design I created my own. Where most marble clocks contain a large number of marbles, this design is minimalist …

“Today, I’d like to share how to build a fixed belt CNC plotterthat has a very different construction from the others, in that both axes XY are made from fixed timing belts and their stepper motors are hidden inside …

“I developed a new clock mechanism to address the issues present in existing mechanical clocks. Famous split-flap displays exhibit undesirable parting lines in the text, and their display surfaces cannot be tilted as they rely on gravity. Numechron-type clocks feature …

“Hi, in this project I will show you how I made this great-looking 3D-printed Hollow clock. Hi, in this project I will show you how I made this great-looking 3D-printed Hollow clock. I saw this project on Thingiverse a few …

“I created a DIY controller box using single-axis joystick modules and Arduino Nano to control an RGB LED, servo motor, and stepper motor! In this project, I demonstrate three different use cases for single-axis joysticks with an Arduino Nano microcontroller …

“Automation of a microscope Z-stage by Arduino + stepper 28BYJ48, controlled by serial dialogue, with emulated keypress after each movement. To understand the meaning of this project, you should be confident with the concepts of focus stacking in macrophotography or photomicrography …

“A simple digital clock with sequential Geneva drives. - Easy time adjustment using sliding mechanism to release the engagement of Geneva drives - Easy to make with only 9 printed parts - Driven by a single motor - Easy to print without support structure …

“About 3 years ago, I made my own a simple robot arm and published it at: https://www.instructables.com/DIY-SINGLE-ARM-SCARA-ROBOT/. Until now, many people, especially students continued to ask me questions about how to “HOMING …