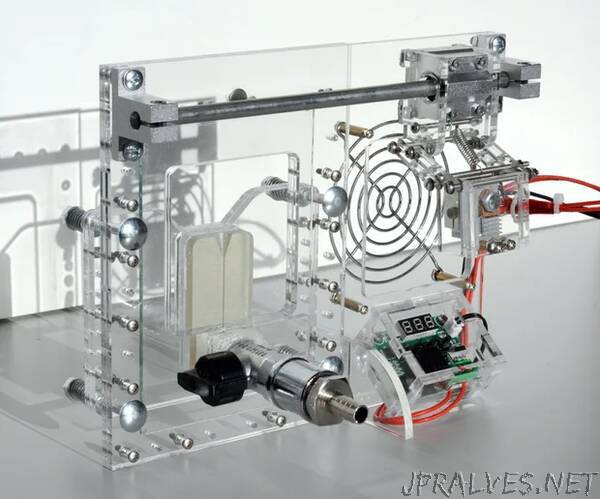

“This instructables guides you through the steps of making a Vacuum Fiber Drawing (VFM) machine, a tool to designed for chemists/soft-roboticists/academics to rapidly design and iterate LCE actuators.

Tools needed:

- Laser cutter

- 3D printer

- Screwdriver

- Glass drill

- superglue

- hot glue

- wirestrippers

Parts needed:

- 5mm perspex

- Glass pane +/- 10x15cm (max 2 mm thick)

- Fan guard +/- 9x9cm

- XH-W1209 thermostat

- Female DC Jack

- 12V 3 amp powersupply

- Regular 3D printer heater block with M6 thread

- 6mm heater cartridge

- 1/2” xM24 air valve

- 1/2” coupling

- 1/2” hose connector

- Linear bearing SCS8UU

- 8mm by 235mm metal rod

- 8mm rail support

- Spring 10x15mm (4x)

- Tensionspring 5x15mm

- Neodymium magnet 10x2mm (5x)

- Heat sink +/- 1x1cm

- Breadboard +/- 10x30x2mm

- felt

- zipties

- Nylon Bolt M3x8 (4)

- Bolt M3x20 (28x)

- Bolt M3x60 (6x)

- Bolt M3x25 (4x)

- Bolt M3x8 (4x)

- Spacer M3x20 (4x)

- M3 nut (44x)

- M3x10 Nylon spacer (2)

- M3x20 metal spacer (4x)

- Bolt M5x20 (4x)

- M5 nut (4x)

- Coach bolt M6x60 (4x)

- Bolt M6x12

- M6 nut (4x)

- Silicone”