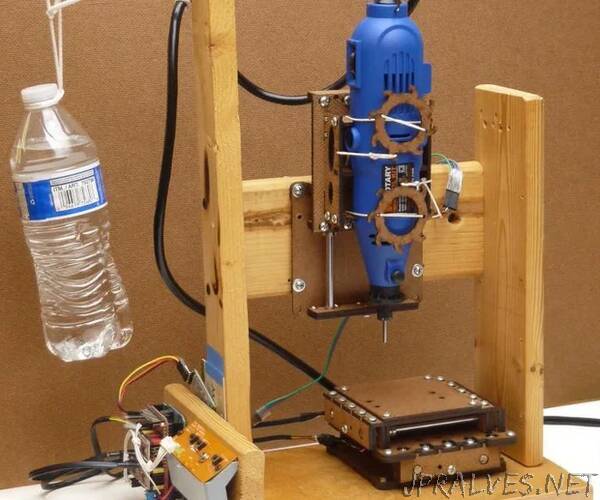

“As far as I know as of writing: this is the lowest cost 3-axis CNC mill you can build from available parts and repeatable instructions. It’s small and I hadn’t even thought of trying to cut steel before starting this sentence, but it’s small and that reduces the “more stuff” cost too. I’ve been milling acrylic and hardboard/HDF with encouraging results. A few trials with aluminum [*] were limited by pilot error rather than the machine and that was all I wanted to know at the time.

This little mill uses three similar but different versions of “a cheap compact linear motion slide”. That’s a huge Instructable that does the heavy lifting for this project. As a precursor to publishing this ‘ible, I put some time into at least trying to make the slide ‘ible fairly complete. At least for now, this ‘ible remains a little more sparse. Hopefully detail in the “cheap slide” ‘ible will support the relatively lightweight presentation here. I also hope to put some more time into filling in the sparse corners of this ‘ible anyhow.

However, the Main Things are in here:

SVGs for the laser cut parts

dimensions for a frame

already referenced the ‘ible re how to assemble a slide

link to CAD

This ‘ible intentionally focuses on building the machine. No instantly gratifying milled part will fall out at the end. CAM is harder than one ‘ible. The point of this project is to lower the entry ticket cost to start learning CAM.

How low is “low cost”? Here’s a bill of materials verified May 2021 for US delivery:

$22.75 - 3x motors

$5.26 - 10x bearings (1 extra)

$9.78 - 9x rods

$1.52 - 100x screws

<$1.00 - ~9”x30” 1/8” hardboard

Total <$40.31 (+tax) if you have to buy everything. A quarter of that for 6mm rod scavengable from dead printers of many kinds.

That pays for the 3-axis machine. Costs I don’t feel bad about leaving out include:

rotary tool - because that’s a generally useful tool that you either have or this is the excuse you’ve been waiting for to get one.

frame - I build the proof-of-concept, used in photos here, from a few poor scraps and drywall screws without a saw to cut anything.

controller - because that’s portable between projects — or ~$10+misc part scrounge (example) if you want to count it.

time - yeah… don’t ask. because I don’t know. (actually, I can put one of these together pretty quickly now)

Please try building one for yourself and share how you fare!

[*] this will be a footnote while the CNC contest is on because this was post-deadline: bona fide cutting aluminum.”