“Now here’s something I was not expecting. Previously, I tried to drive this stepper motor with the driver board that came with the motor. My main goal was of course keeping the accuracy of the tiny motor safe and then testing at which speed I could get the maximum torque it could produce. Depending on the driving method, I came up with 300gcm when it was driven using half stepping and 380gcm when I switched to full stepping. Those were actually good results considering that the datasheet predicted these numbers more or less.

Now this kind of motor is not really up-to-date with modern technology. Unipolar stepper motors are not that common anymore. Bipolar steppers are twice as efficient with the same amount of copper on the internal windings. Even in full stepping mode, a unipolar stepper still has 2 out of four wires not active all the time. So basically, if there was a way to run current through all windings in the motor at all times, the thing would be stronger and faster.

That’s what happens in a bipolar stepper motor. It has only two windings instead of four in a unipolar stepper. Both windings can be activated all the time, but their polarity is switched in four steps. This means that this kind of motor only has four wires instead of 5 (or 6 or 8). The tricky part is changing the polarity. That cannot be achieved by the simple driver board that came with this motor. It only activates one or two out of four outputs, but current always flows in one direction.

What if we could change the wiring of this motor, thus converting it to a bipolar model? All you would need to do is cut the red wire in the scheme above and then ignore the center connection marked 2+3+6+7. The result would be something like the left drawing.

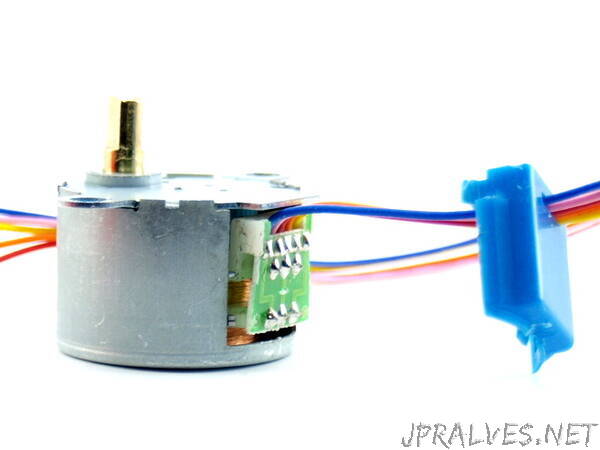

I found out that this is very easy with this motor. All you need is a sharp knife and a tiny screwdriver. Use the latter to remove the blue plastic cap that hides a small PCB. On this PCB, you can see eleven solder points. All it does is fixate the wiring of this stepper (which can be either unipolar or bipolar by design) into a unipolar type by connecting the center of the two windings. If we cut this connection and ignore it in our scheme, what’s left is a real bipolar stepper motor.”