“If you’re like me, you probably invest too much time into projects that others may think have a very distant payoff, or little payoff at all! Over the last several months, I’ve been working on such a project. The main project is a Head Up Display (HUD) for my car that will show basic vehicle information (such as speed) alongside in depth data relevant to diagnostics and off road driving. I was dragged into a bit of a rabbit hole when I got hooked on the idea of including a graphic of the vehicle’s drivetrain that displays, in real time, exactly which wheels are slipping when traction is poor (this is an AWD vehicle). This rabbit hole lead me to design a control board I’m calling Telemetry Master.

Wheel Speed Sensors

To create the functionality I wanted, I decided using my vehicle’s existing wheel speed sensors was the logical choice. Wheel speed sensors can vary in design and operation. My particular sensors are mounted in each wheel hub assembly and are permanently magnetic so they induce a magnetic field in an exciter ring that rotates with the output flange of the hub. The exciter ring is a metal disc with 60 teeth on its periphery. The intensity of the magnetic field varies by how much ferrous material it is permeating, so as the teeth of the exciter ring pass by the sensor, a sine wave of alternating current is induced back across a coil within the sensor. The frequency of the output wave is proportional to the speed at that wheel.

For my vehicle, wheel speed sensor data informs how the Anti-Lock Brake System(ABS) needs to manage traction control and braking (see note below). My goal when designing Telemetry Master was to access this same data without interrupting the ABS computer’s access to it.

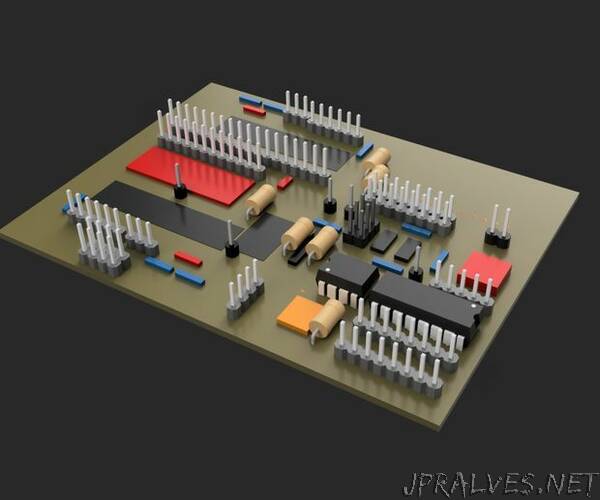

Producing the Board

To create the Telemetry Master board, I will first discuss a method referred to in the RepRap community as “Scratch n’ Etch.” This method involves using a CNC platform like a 3D printer to scrape away a mask coating from the copper board with a sharp scribe point. The exposed copper can then be etched away, leaving isolated traces. In later boards, I experimented with the traditional Toner Transfer method.

A Note on Vehicle Safety

Tinkering with electrical systems related to your vehicle’s ABS may not be a great idea on daily drivers or high performance vehicles where traction control is important to handling.”