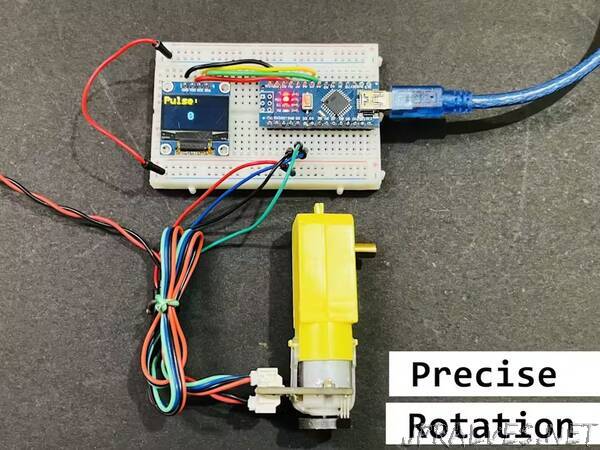

“To precisely control the BO motor or to make any low cost project using PID we can consider this types of encoder integration with motors.

Geared Dc motors are used in a lot of hobby projects like in making some kind of robot car and moving robotics. But for precise movement it is very important to use special kind of motors. For example for a balancing robot, we have to use stepper motors (proper stepping of wheel). Because in balancing the movement needed is very precise and normal motor can not complete the task. But there is one solution to these problems where we do not want to use stepper motors but want precise movement then encoder can be used with BO motors.

This encoder just record the rotation speed and direction and convert them into a pulses which can be paired with a microcontroller and driver to precisely change the voltage levels according to the desired pulses needed. These pulse control finally decide the movement speed of motor and using BO motors is very cost effective solution.

How magnetic encoder works:

An electronic magnetic rotary encoder utilizes magnetic fields to measure the rotation of an object. It consists of a magnetized rotor and a stationary sensor. As the rotor rotates, the sensor detects changes in the magnetic field and converts them into electrical signals.

These signals are processed to determine the rotational position, speed, and direction of the object. The sensor can be based on various technologies, such as Hall effect sensors or magneto resistive sensors, which detect the magnetic field variations. By analyzing these signals, the encoder provides accurate rotational data, making it useful for applications such as motor control, robotics, and industrial automation.”