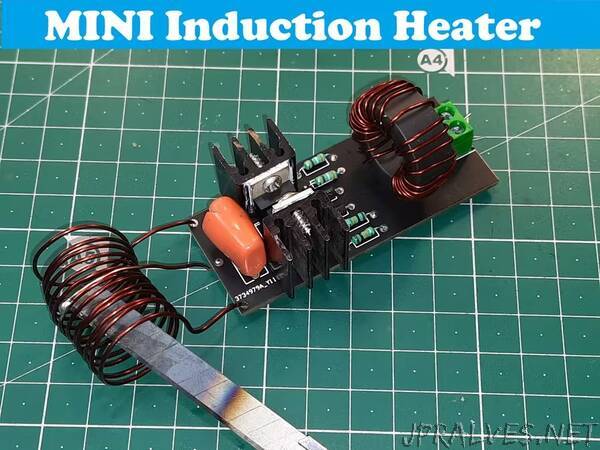

“A heater similar to commercial one and made for low end tasks. Like PVC or plastic cutting or to heat small knifes and cutters.

Hello guys, as you know I don’t have any 3d printer till now. So, I made my projects and 3d styled cases using PVC pipes. The cutting and molding of PVC can be done using heated knife or hot cutter. Heating a knife on gas stove or by electric nichrome wire is not recommended in this case.

That’s why induction technique come into play. An induction heater consists of an electromagnet and an electronic oscillator that passes a high-frequency alternating current (AC) through the electromagnet. The rapidly alternating magnetic field penetrates the object, generating electric currents inside the conductor, called eddy currents.

I want to build my own mini-induction heater for hot knife PVC cutting. You can see the commercial samples available on amazon and eBay. I will put my knife inside the coil and this will work fine for cutting plastic or PVC pipes. The main advantage is that it reduce the time of heating because induction can almost heat properly a small conductor (iron/steel) in 2 seconds @250degrees.

Supplies:

1) IRFZ44N

2) 10K resistor

3) 390ohms resistor

4) 105k capacitor

5) Toroidal Coil

6) Induction coil

7) Diodes fast switching

8) Screw terminals

9) 12v @10A power supply

10) Custom PCB( JLCPCB)”