“Hello everyone! This project has been developed for my final

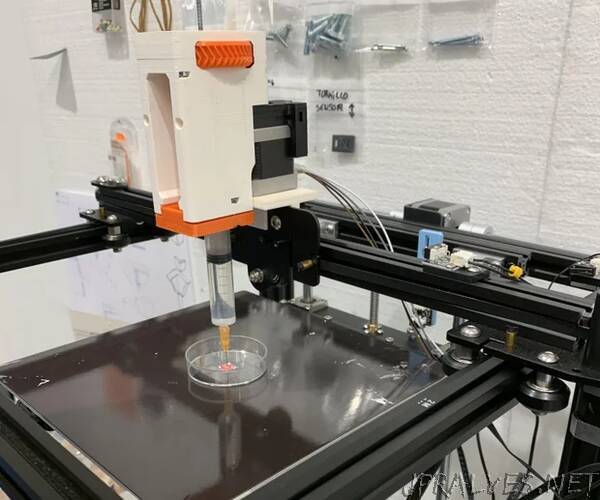

Engineering degree project. The aim was to convert a commercial FDM 3D printer into a bioprinter with the minimum budget possible. This proposal comes from the challenge that bioprinters are usually very expensive, ranging from 20.000€ to even 500,000€.

Therefore, we wanted to make this technology available to every maker, and the best tool that a DIYer has is its own 3d printer. With very few and simple tools, filament, and the knowledge anyone who wants to experiment with bioprinter will be able to do so.

By doing so, fields such as tissue engineering could experiment a growing interest from the maker community, and because other people that are not doctors and don’t work in labs, could contribute in their own way to the development of this area.

We are contributing to the open-source community in the same way we have nourished ourself from it. The original bio-extruder’s credit goes to T.JHinton, who designed the “Replistruder v3.0”, which we later modified for our necessities. The bio-extruder mount has been inspired in Madau3D’s “Ender 3 Direct Drivinator”.

This project also includes a design that has been entirely designed by our team. It’s a thermal control system, which allows the printing material to stay at a constant temperature up to 40ºC, or 104ºF. We wanted the whole project to be accessible, so the system only uses available components, such as ABS printed parts. The heating system uses the hot end from the 3d printer itself.

As for what are the possibilities with this printer, we have been using hydrogels, which are advanced materials that hold a large amount of water while maintaining the structure, but there are many more possibilities, like printing chocolate, gelatine or even meat. Checkout Novameat startup for example.

Supplies

- Ender 5 or Ender 5 Pro

- M3 x 20,30 and 40 bolts (20 units each aprox.)

- PLA and ABS filament

- Threaded rod M3 x 120 mm

- 28mm Ø, 1mm thich and 64mm long copper bar

- 4x female-male jumper cables

- Tin soldering iron kit

- Metal files or other tools for resizing the bolts

- 10ml MB syringes”