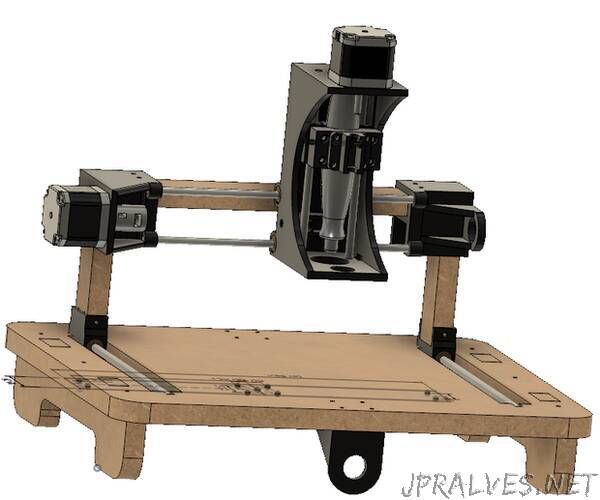

“After building my 3D printer out of old printers and MDF and using it for a few years, I want to expand my machine shop with a CNC machine. Before to go and buy expensive aluminium extrusions and electronics, I decided to build a small machine out of the parts I had lying around from my 3D printer project and printer dismantelement.I used 6mm smooth rods and brass bearings pretty common in paper printers as guides for my axes, M6 threaded rods to drive those axes, the whole structure is made from 16 mm thick MDF and 3D printed parts assembled with common M3 countersunk screws from the hardware store.

The machine is controled using an Arduino Uno and a CNC shield running grbl.

The whole machine was designed on Fusion 360.

All the parts plans for cutting and printing are available on my thingiverse account :

https://www.thingiverse.com/thing:4440477 , (pdf and stl files are available as well as Fusion 360 archives)

Supplies:

Electronics :

-3 NEMA 17 stepper motors

-Arduino Uno

-Arduino CNC Shield

-3 stepper drivers (A4988, DRV8825, TMC…)

-OPTIONNAL 4 endstop switches 12,6 x 6,5 x 5,7 mm (you can get them from old mouses)

-12V DC 200W power supply

Mecanics :

-400*600 16 mm MDF board

-12 brass bearings (10mm external diameter, 6 mm internal diameter, 8mm length, 2 mm thick 14mm diameter flange

-2x 6 mm smooth rods 222 mm long

-2x 6 mm smooth rods 232 mm long

-2x 6 mm smooth rods 150 mm long

- M3 countersunk screws

-M3 6mm inserts

-1 m M6 threaded rod

-3x 5 to 6 mm shaft couplers

Printed Parts

-2 (1 mirrored on y) CNC_y_brass_linear_bearing_mount_x2_MIRROR1

-1 CNC_dremel_flexible_clamp_x1

-1 CNC_x_bearing_mount_x1

-1 CNC_y_bearing_mount_x1

-1 CNC_y_M6_nut_mount_x1

-1 CNC_y_motor_mount_x1

-1 CNC_z_carriage_x1

-1 CNC_z_M6_nut_mount_x1

-1 CNC_x_carriage_x1

-1 CNC_x_motor_mount_x1”