“This is “yet another” PID temperature controller. I’ve made this one, because bought one was crappy and I needed something solid. There are two or three other DIY controllers “on the market” but this one, at least I see it this way :), is much more robust and has all features I needed.

Key features:

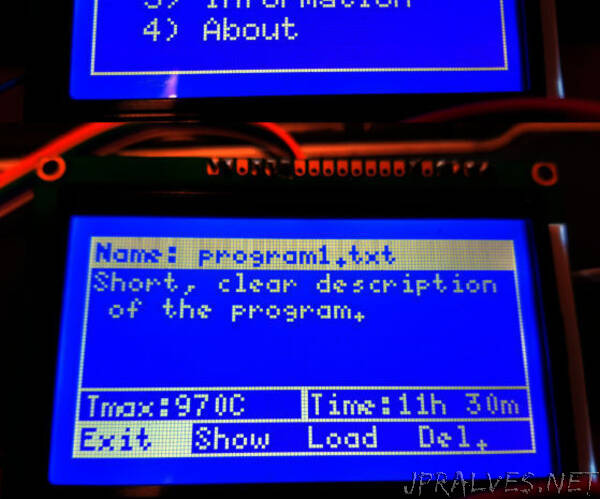

interface accessible both from LCD screen and WWW webpage

unlimited (only by storage) kiln programs number,

program file size limited to 10KiB (but this is artificial limit - can be extended)

internal ESP storage for programs, data, logs (perhaps later SD - but I’m not sure yet)

local preferences on disk, editable with Web interface

online monitoring, program management, editing, graphs and kiln controll

build in clock synchronised with NTP servers (if Internet connected)

safety features build in (temperature run out protection, probe failure, SSR failure, kiln insulation failure)

simply cool and cheap (comparing to commercially available products) all in one solution

Supplies:

- ESP32-Wrover board

- MAX31855 breakout board (or two)

- K-type thermocouple

- DC->AC solid state relay

Kind of optional, but recommended:

- 128x65 dot matrix LCD 12864B v2

- Rotary encoder with button

Optional:

- DC/AC secondary relay - like SLA-05VDC-SL-C (240V/30A) mechanical relay

- Additional MAX31855 board with K-type thermocouple for housing temperature measuring

- Perhaps a kiln :)”