“Servos (also RC servos) are small, cheap, mass-produced servomotors used for radio control and small-scale robotics. The are designed to be easily controlled: the position of the internal potentiometer is continually compared to the commanded position from the control device (i.e., the radio control). Any difference gives rise to an error signal in the appropriate direction, which drives the electric motor either forwards or backwards, and moving the shaft to the commanded position. When the servo reaches this position, the error signal reduces and then becomes zero, at which point the servo stops moving.

Radio control servos are connected through a standard three-wire connection: two wires for a DC power supply and one for control, carrying a pulse-width modulation (PWM) signal. The standard voltage is 4.8 V DC, however 6 V and 12 V is also used on a few servos. The control signal is a digital PWM signal with a 50 Hz frame rate. Within each 20 ms timeframe, an active-high digital pulse controls the position. The pulse nominally ranges from 1.0 ms to 2.0 ms with 1.5 ms always being center of range.

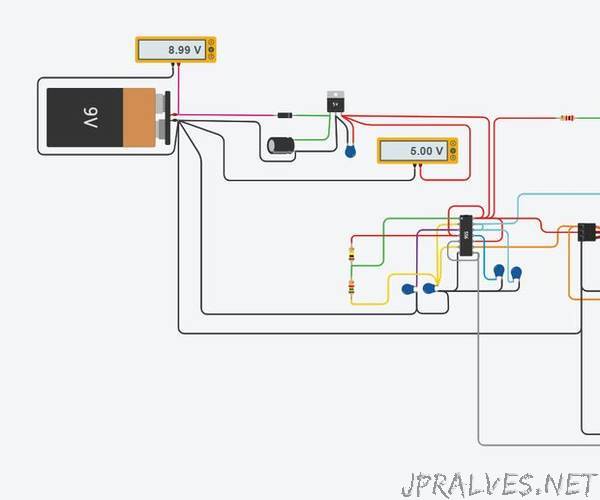

You dont need a microcontroller or computer to control a servo. You can use the venerable 555 timer IC to provide the required pulses to a servo.

Many microcontroller based circuits are available on the net. There is also a few circuits available to test servo with based on single 555’s, but I wanted precise timing without the frequency varying at all. Yet it had to be cheap and easy to build.”