“An analog Frontend shield for the Scoppy Oscilloscope, running on the RP2040

This post will look at my prototype Analog front-end for the Scoppy RP2040 Oscilloscope. It is important to state right from the beginning that this circuit is one of the 5 recommended designs from the Scoppy Website. I have only moved it from the breadboard design as published, onto a PCB.

The entire circuit, with all of the original designer’s writeups, is available here

So, why use someone else’s circuit? Well, the reason for this is two-fold.1) The circuit designer also designed the firmware, so it stands to reason that his circuit will be optimised for use with the firmware.2) Using his circuit provides a solid reference, making it possible to test the firmware for correct operation, and later on, providing a base for my own design – if and when I do decide it is worthwhile to actually design my own.As I already have a proper oscilloscope as well as a logic analyser, this entire exercise is purely academic, I find the Scoppy project interesting, and as such, I would like to see how it compares with my commercial products ( while also knowing that it won’t be a very fair comparison ).With all the limitations, I am however still quite impressed at the level of use that you can get out of this very simple device. It is definitely quite useful for a beginner.

What is on the PCB, and what did I change?

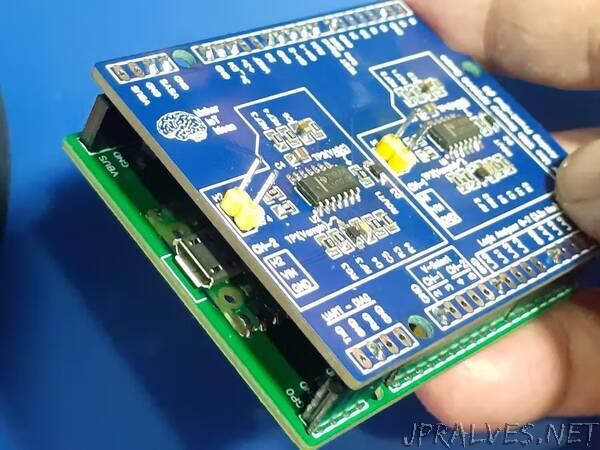

The PCB is a dual-layer shield that is designed to be used with the MakerIOT2020 Raspberry Pi Pico Carrier board. The shield is directly powered by the carrier board.The original Analog Front-End #3 circuit featured a single channel input, capable of accepting a -18.0v to 18.0v signal input. My changes were limited to doubling up on that circuit, to provide two channels.

This design builds on Design 2 and adds over and under voltage protection to the analog front end. After all, we won’t have a cheap oscilloscope if we keep frying our components!

I’m assuming here that the minimum and maximum voltages that will be applied to the input of the scope will be -18V and +18V respectively. It has been tested from -18.5V to 18.5V (two of my 9V batteries in series) but of course If you decide to use this design you are doing so at your own risk. I personally wouldn’t use Scoppy with an expensive phone/tablet just in case something unexpected goes wrong (better to use an old, obsolete phone that is no longer used for anything else) – especially when dealing with higher voltages – but of course you can do what you like.

Protecting the Op-Amp input(s)

First of all we need to protect the op-amp. In this design we’ll be using an LM324 op-amp, which is very similar to the LM358 but contains four individual op-amps rather than two. We’ll be using three of these op-amps. The reason for this will be explained later.

According to the datasheet for the LM324 the allowed input voltage range goes from -0.3V to 32V. Of course 32V is above the maximum expected voltage (18V) and so we don’t need to worry about over-voltage protection. However we do need to ensure that the voltage at the input pins don’t go below -0.3V. A schottky diode can be used to clamp the voltage to something above -0.3V (D1 in the schematic).

One thing that needs to be considered when selecting the diode is its reverse current. The 1N5817 has a very low forward voltage but high reverse current and this results in a voltage drop at the input of the op-amp (in the order of 100mV). Presumably this is because it draws current through the high value input resistor (Rg1). The 1N5711 has a much lower reverse current specification and I couldn’t discern any voltage drop when this was inserted into the circuit. However, its forward voltage (at the current expected in this part of the circuit) is very close to the minimum allowed voltage of -0.3V. To be safer I prefer to use something like a BAT46. It does result in a voltage drop of a few millivolts but the clamped voltage is more like -0.23V.”