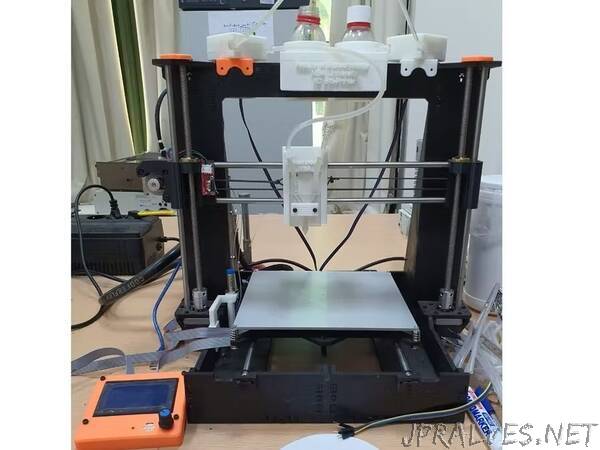

“Fabrication of a 3D bio-printer from an off-shelf 3D printer (Prusa). The bioprinter is used for constructing 3D scaffold from hydrogels

The story

Additive manufacturing tech such as 3D printing is the manufacturing process to obtain physical objects from CAD files, through adding layer-by—layer of a specific material (Haleem, et al., 2019; Chen, et al., 2020). 3D printing has had a rising progress which led to the development of revolutionary field called 3D bio-printing (Sanchez, et al., 2020; Vanaei, et al., 2021). In this research, we are introducing an approach to a low cost DIY 3D-Bioprinter converted from an Off-shelf 3D printer. Later, 3D bio-printing strategies are introduced using a mixture of natural polymers in hydrogel to produce a simple scaffolds. Followed by their application in the medical field.

Why this project?

Tissue engineering is a promising field in regenerative medicine these days. Its a cutting edge tool and many laboratories are interested in the 3D cell culturing research and techniques. However, the toolkit to such research are not that cheap, most of time are not affordable at all. Take example of the commercially available 3D Bioprinters which are very expensive, ranging from 10, 000-100, 000$, which is mostly not affordable by many emerging scientific laboratories. On the other side the open source community is very rich and informative in enormous fields of high-tech. Thus we decided to contribute to the scientific community with our own efforts by replicating previous DIY 3D-bioprinter projects and enhancing it by adding our touch to simplify the over all process. In other words, we are taking from the open source community and we return our enhanced product to the same society, with pleasure.

How does it work?

We started by assembling the Open-sourced Prusa I3 and we ended up changing the original I3 extruder and the hot-end nozzle with two FDM-printed Peristaltic pumps and DLP-printed double syringe nozzle.”