“About two years ago, I made a little LED tree as a gift. An extremely simple design with 17 white 0603 LEDs soldered to magnet wire, twisted and bent to make branches, and combined them to a small LED bonsai. Electrically, all LEDs are wired in parallel and connected to 4.5 V via an LDR. This lets the tree react to the ambient brightness and helps it to great battery life.

In fact, it is still glowing nicely with its first set of batteries! This most basic circuit combines a remarkably natural analogue brightness control with efficient white LEDs, so long battery life isn’t too surprising. Still, I didn’t quite expect a battery life this long.

This blog post isn’t about this particular set of entangled magnet wires and LEDs, however. It’s about another bigger, tanglier mess of enamelled wire and LEDs.

The plan

It started when I found out I could get improbably small RGB LEDs. I immediately wanted to one-up my last LED tree. Let’s see where I could take it, shall we?

Using RGB LEDs of course would mean retiring the superb efficiency, but would allow for more impressive visuals. And, of course, the mere challenge of using these tiny LEDs in a circuit sculpture itself was quite appealing. This one was going to be a gift as well, but that doesn’t mean I couldn’t have some fun building it. Crucially, I didn’t have a strict deadline (this endeavour wasn’t suitable for a last-minute gift) so I was able to experiment a bit.

This post goes into some design decisions which made the technical aspects as interesting as the end result, at least in my opinion. It also covers some tricks I used to avoid going mad while dealing with the touchy rats-nest of wires making up the tree’s branches and roots.

Hardware

While I actually wrote a software proof-of-concept first to make sure I could pull everything off with the hardware I imagined, this post reads nicer if I start with the craftwork and slowly work my way towards the driving electronics and software.

Soldering LEDs to wires

As basic as it may sound, but the first, and perhaps most crucial step, is sticking blossoms onto branches. Thankfully, the LEDs linked above hold up under soldering temperatures quite well; otherwise this project probably wouldn’t have been possible at all.

Still, what isn’t too hard for basic white LEDs is a lot more involved for RGB LEDs. When soldering a single colour LED’s two pins to wires, only so much can go wrong: you can have a short, open circuit or swapped pins, all of which are immediately obvious when testing with a multimeter from the other end. With four pins, there are a lot more failure modes; manually probing everything until each LED is soldered correctly wasn’t going to cut it.

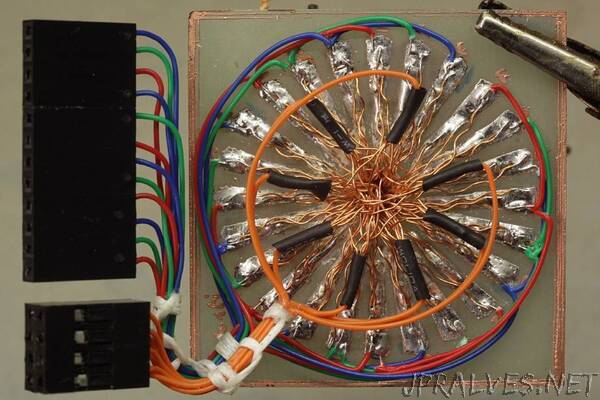

Instead, I made a simple test signal generator I could connect to one end of the cable. The circuit below ensures that all three colours independently either light up or go out if an RGB LED is connected to its four outputs, no matter how exactly. This means all possible faults are immediately detectable: if one colour is missing, there is an open circuit—if two are always lit at the same time, there is a short.”