“Earlier this year we released designs for the Engravinator and while designing that, I caught the CNC bug… hard. I’ve been using all sorts of CNC-type machines for years, of course, already owning multiple 3D printers, lasers, and CNC routers. What I mean is the bug for building my own.

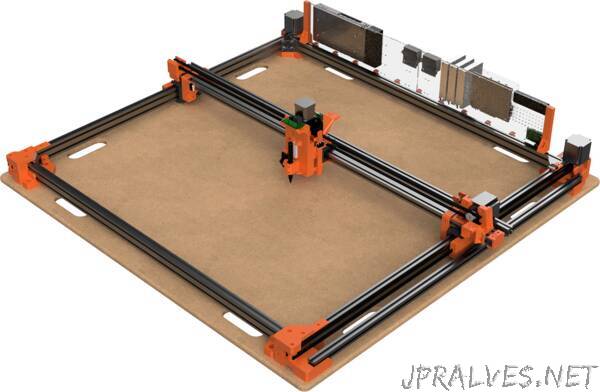

The Engravinator is a great little machine and that’s what it’s designed to be. Small. But I quickly wanted to be able to work with much larger material and have a level of flexibility that the Engravinator just did not afford. So for a few months, the idea of a roughly 1 meter by 1 meter, 2-axis motion system rumenated in my mind.

It needed to not only have a large working area but have but the flexibility to use more than just a laser or pen as a toolhead. It needed to be a development platform for all my computerized motion control needs. And while I wanted it to be accessible in terms of the ability to replicate the design (which of course makes future repairs simpler for myself as well), I wanted the over-arching philosophy to be:

So when things, well… got crazy in March 2020, I decided it was a good time to barricade myself in the shop and start chipping away at a design. And, well, it turned it out to be a pretty awesome machine, if I do say so myself :)

Specs

Let’s get right to the good stuff, shall we?

800mm x ~750mm working area (Y axis depends on current tool)

2040 Aluminum extrusion frame

ExoSlide Linear slides for both axis

9mm wide GT3 heavy-duty belts

Nema 23, 1.2 Nm motors (1 on X and 2 on Y)

DM542Y 4A motor drivers

40mm travel Z-axis

SmoothieBoard 5X

Interchangeable tool heads with common power and signal connectors

5V, 12V, and 24V available for tools and accessories

Travel speeds up to 1000mm/s on X and 500mm/s on Y

Built in white and UV LEDs

Tools

Originally I had considered creating a system that could do automatic tool changes, likely using the new E3D tool changer specification. But I quickly realized that I wanted to have larger tools than that could support and that a 3 minute manual change was perfectly fine for my needs. It could certainly support an automatic change system, I just didn’t need the feature. But getting even a manual tool change down to a couple minutes still took some careful consideration.

The core of the system is a series of custom designed circuit boards each with the same mounting pattern, basic size, and electrical connections.”