“New method allows scientists to precisely measure the strength of nanomaterials only a few atoms thick

The physical properties at the surface of nanomaterial structures become much more prominent as they approach atomic scales. In a recent study, Japanese scientists accurately measured, for the first time, the mechanical strength at the surface of gold nanocontacts as they were progressively stretched down to only a few atoms. Their findings, along with their innovative nanomechanics measurement method, could open doors to nanoelectromechanical systems and next-generation sensors.

Miniaturization lies at the heart of countless technological advances. It is undeniable that as devices and their building blocks get smaller, we manage to unlock new functionalities and come up with unprecedented applications. However, with more and more scientists delving into materials with structures on the atomic scale, the gaps in our current understanding of nanomaterial physics are becoming more prominent.

For instance, the nanomaterial’s surface represents one such knowledge gap. This is because the influence of surface quantum effects becomes much more apparent when the surface-to-volume ratio of a material is high. In nanoelectromechanical systems (NEMS), a current hot topic in research, the physical properties of the nanomaterials greatly differ from their bulk counterparts when their size is reduced to a few atoms. A solid understanding of the mechanical properties of nanowires and nanocontacts—integral components of NEMS—is essential for advancing this technology. But, measuring them has proven a challenging task.

Against this backdrop, a research team from Japan recently achieved an unprecedented feat when they managed to precisely measure the elastic modulus of gold nanocontacts stretched down to a few atoms. The study, published in Physical Review Letters, was led by Professor Yoshifumi Oshima of Japan Advanced Institute of Science and Technology (JAIST). The rest of the team included post-doctoral research fellow Jiaqi Zhang and Professor Masahiko Tomitori from JAIST, and Professor Toyoko Arai of Kanazawa University.

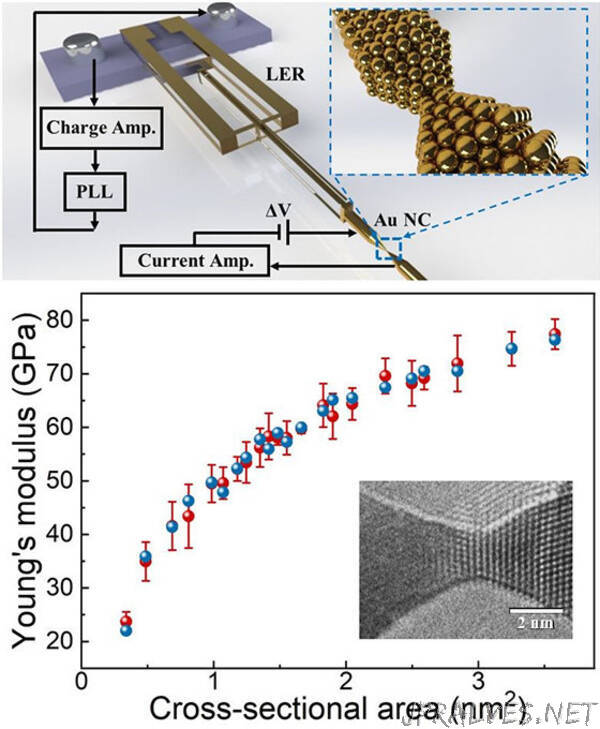

To observe the gold nanocontacts as they were mechanically stretched, the researchers used transmission electron microscopy (TEM) in ultrahigh vacuum. This was essential to ensure that the surface of the nanocontacts stayed perfectly clean during the measurements. Meanwhile, to accurately measure the Young’s modulus (a measure of stiffness) of the nanocontacts, the team resorted to an innovative technique they had previously developed. They put a quartz length-extension resonator (LER) in a TEM holder and attached one side of the nanocontact to it. In their setup, the resonant frequency changed depending on the “equivalent spring constant” of the gold nanocontact, which is related to the material’s Young’s modulus. “With our approach, which we named the ‘nanomechanics measurement method,’ we can accurately measure a nanomaterial’s equivalent spring constant while simultaneously observing it using TEM and measuring its electrical conductivity,” explains Prof. Oshima.

Using this strategy, the researchers experimented with gold nanocontacts that they progressively stretched without breaking. They observed how individual atoms rearranged themselves into new layers as each nanocontact was stretched, and calculated how the Young’s modulus changed depending on its size. Whereas the Young’s modulus of the inside of the nanocontacts was equal to that of bulk gold (90 GPa), that of the surface of the nanocontacts turned out to be only 22 GPa.

With this knowledge, the team demonstrated that the overall strength of gold nanocontacts is governed by the softness of their outermost surface layer. “Our findings clarify why the strength of a nanomaterial differs from that of bulk crystals depending on its size, and our approach allows us to estimate the Young’s modulus of any type of nanosized gold,” remarks Prof. Oshima. “Most notably, our results provide appropriate guidelines for the design and development of nanowires and nanosheets for NEMS. This could open doors to promising pressure, gas, and sound sensors, among other applications,” he adds.

Aside from NEMS, the team expects that their results, together with their measurement method, could have potential implications for chemistry since chemical reactions depend not only on the structure or the electronic state of the catalyst but also on atomic-scale vibrations on its surface. As these atomic vibrations are related to the material’s surface strength, it is possible that the proposed methodology could help us find new ways to control chemical reactions.

Let us hope future studies would elevate our understanding of nanomaterials even further.”