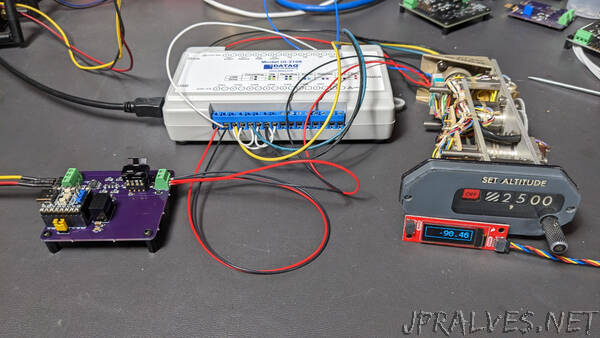

“This project uses modern data acquisition hardware to track the shaft angle of a synchro transmitter as the shaft is turned through various angles. How difficult could it be to get the absolute angle of a position sensor from the 1980’s that was originally developed during the WWII era into a modern computer? Turns out, it’s more difficult than it seems, and for most hobbyist applications, more difficult than it’s worth. Read on to find out more.

The synchro, like a potentiometer or encoder, is a device for converting a mechanical rotational position into an electrical signal representing that position or a change in that position.

Potentiometers are inexpensive and easy to interface to micros with ADCs. Encoders range from inexpensive, crude mechanical incremental encoders to expensive, precision optical absolute encoders. Encoders have digital outputs and are easy to interface to micros too.

Synchros, on the other hand, can be expensive and require the user to generate and process AC waveforms. Synchros have several advantages over their more common counterparts that might lead one to choose a synchro instead of potentiometer or encoder:

- Synchros always provide the absolute position of the mechanical shaft without requiring a homing sequence.

- Even basic synchros have precision and accuracy measured in arc minutes. Only high-end absolute position optical encoders can come close to synchro’s resolution.

- Synchros have ratiometric outputs that provide high noise immunity.

- Synchros are transformers and thus inherently provide galvanic isolation and high common-mode rejection of interference.

- Synchros are more reliable than potentiometers and encoders.

The major downsides of a synchro:

- Synchros are expensive but they’re still less than an absolute optical encoder with the same precision.

- Synchros are transformers and thus only work with AC signals.

As a result, synchros tend to be used mostly for military, aerospace, industrial, and automotive applications that demand their precision, accuracy, and reliability.”