“The installation of LHCb’s all-new Vertex Locator is part of a major upgrade that will extend the experiment’s capabilities to search for physics beyond the Standard Model, describe Stefano de Capua, Wouter Hulsbergen and David Hutchcroft.

The first 10 years of the LHC have cemented the Standard Model (SM) as the correct theory of known fundamental particle interactions. But unexplained phenomena such as the cosmological matter–antimatter asymmetry, neutrino masses and dark matter strongly suggest the existence of new physics beyond the current direct reach of the LHC. As a dedicated heavy-flavour physics experiment, LHCb is ideally placed to allow physicists to look beyond this horizon.

Measurements of the subtle effects that new particles can have on SM processes are fully complementary to searches for the direct production of new particles in high-energy collisions. As-yet unknown particles could contribute to the mixing and decay of beauty and charm hadrons, for example, leading to departures from the SM in decay rates, CP-violating asymmetries and other measurements. Rare processes for which the SM contribution occurs through loop diagrams are particularly promising for potential discoveries. Several anomalies recently reported by LHCb in such processes suggest that the cherished SM principle of lepton-flavour universality is under strain, leading to speculation that the discovery of new physics may not be far off.

Unique precision

In addition to precise theoretical predictions, flavour-physics measurements demand vast datasets and specialised detector and data-processing technology. To this end, the LHCb collaboration is soon to start taking data with an almost entirely new detector that will allow at least 50 fb–1 of data to be accumulated during Run 3 and Run 4, compared to 10 fb–1 from Run 1 and Run 2. This will enable many observables, in particular the flavour anomalies, to be measured with a precision unattainable at competing experiments.

To allow LHCb to run at an instantaneous luminosity 10 times higher than during Run 2, much of the detector system and its readout electronics have been replaced, while a flexible full-software trigger system running at 40 MHz allows the experiment to maintain or even improve trigger efficiencies despite the larger interaction rate. During Long Shutdown 2, upgraded ring-imaging Cherenkov detectors and a brand new “SciFi” (scintillating fibre) tracker have been installed. A major part of LHCb’s metamorphosis – in process at the time of writing – is the installation of a new Vertex Locator (VELO) at the heart of the experiment.

The VELO encircles the LHCb interaction point, where it contributes to triggering, tracking and vertexing. Its principal task is to pick out short-lived charm and beauty hadrons from the multitude of other particles produced by the colliding proton beams. Thanks to its close position to the interaction point and high granularity, the VELO can measure the decay time of B mesons with a precision of about 50 fs.

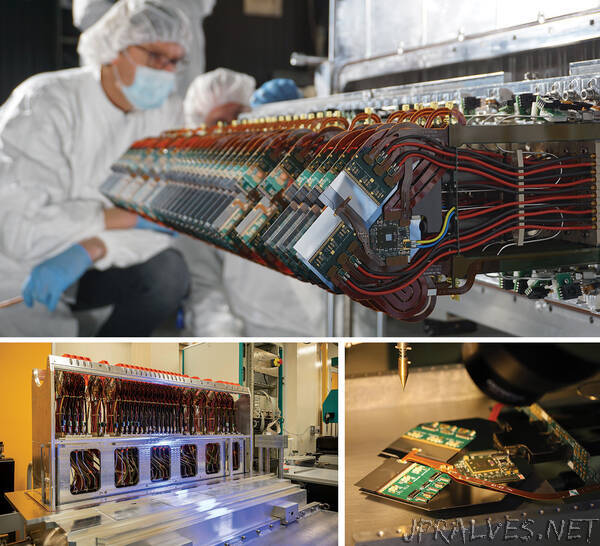

The original VELO was based on silicon-strip detectors. Its upgraded version employs silicon pixel detectors to cope with the increased occupancies at higher luminosities and to stream complete events at 40 MHz, with an expected torrent of up to 3 Tb/s flowing from the VELO at full luminosity. A total of 52 silicon pixel detector modules, each with a sensitive surface of about 25 cm2, are mounted in two detector halves located on either side of the LHC beams and perpendicular to the beam direction (see “Marvellous modules” image). An important feature of the LHCb VELO is that it moves. During injection of LHC protons, the detectors are parked at a safe distance of 3 cm from the beams. But once stable beams are declared, the two halves are moved inward such that the detector sensors effectively enclose the beam. At that point the sensitive elements will be as close as 5.1 mm to the beams (compared to 8.2 mm previously), which is much closer than any of the other large LHC detectors and vital for the identification and reconstruction of charm- and beauty-hadron decays.

The VELO’s close proximity to the interaction point requires a high radiation tolerance. This led the collaboration to opt for silicon-hybrid pixel detectors, which consist of a 200 μm-thick “p-on-n” pixel sensor bump-bonded to a 200 μm-thick readout chip with binary pixel readout. The CERN/Nikhef-designed “VeloPix” ASIC stems from the Medipix family and was specially developed for LHCb. It is capable of handling up to 900 million hits per second per chip, while withstanding the intense radiation environment. The data are routed through the vacuum via low-mass flex cables engineered by the University of Santiago de Compostela, then make the jump to atmosphere through a high-speed vacuum interface designed by Moscow State University engineers, which is connected to an optical board developed by the University of Glasgow. The data are then carried by optical fibres with the rest of the LHCb data to the event builder, trigger farm and disk buffers contained in modular containers in the LHCb experimental area.

The VELO modules were constructed at two production sites: Nikhef and the University of Manchester, where all the building blocks were delivered from the many institutes involved and assembled together over a period of about 1.5 years. After an extensive quality-assurance programme to assess the mechanical, electrical and thermal performance of each module, they were shipped in batches to the University of Liverpool to be mounted into the VELO halves. Finally, after population with modules, each half of the VELO detector was transported to CERN for installation in the LHCb experiment. The first half was installed on 2 March, and the second is being assembled.

Microchannel cooling

Keeping the VELO cool to prevent thermal runaway and minimise the effects of radiation damage was a major design challenge. The active elements in a VELO module consist of 12 front-end ASICs (VeloPix) and two control ASICs (GBTX), with a nominal power consumption of about 1.56 kW for each VELO half. The large radiation dose experienced by the silicon sensors is distributed highly non-uniformly and concentrated in the region closest to the beams, with a peak dose 60% higher than that experienced by the other LHC tracking detectors. Since the sensors are bump-bonded to the VeloPix chips, they are in direct contact with the ASICs, which are the main source of heat. The detector is also operated under vacuum, making heat removal especially difficult. These challenging requirements led LHCb to adopt microchannel cooling with evaporative CO2 as the coolant (see “Microcooling” image).

The circulation of coolant in microscopic channels embedded within a silicon wafer is an emergent technology, first implemented at CERN by the NA62 experiment. The VELO upgrade combines this with the use of bi-phase (liquid-to-gas) CO2, as used by LHCb in previous runs, in a single innovative system. The LHCb microchannel cooling plates were produced at CERN in collaboration with the University of Oxford. The bare plates were fabricated by CEA-Leti (Grenoble, France) by atomic-bonding two silicon wafers together, one with 120 × 200 μm trenches etched into it, for an overall thickness of 500 μm. This approach allows the design of a channel pattern to ensure a very homogeneous flow directly under the heat sources. The coolant is circulated inside the channels through exit and entry slits that are etched directly into the silicon after the bonding step. The cooling is so effective that it is possible to sustain an overhang of 5 mm closest to the beam, thus reducing the amount of material before the first measured points on each track. The use of microchannels to cool electronics is being investigated both for future LHCb upgrades and several other future detectors.

Module assembly and support

The microchannel plate serves as the core of the mechanical support for all the active components. The silicon sensors, already bump-bonded to their ASICs to form a tile, are precisely positioned with respect to the base and glued to the microchannel plate with a precision of 30 μm. The thickness of the glue layer is around 80 µm to produce low thermal gradients across the sensor. The front-end ASICs are then wire-bonded to custom-designed kapton–copper circuit boards, which are also attached to the microchannel substrate. The ASICs’ placement requires a precision of about 100 µm, such that the length and shape of the 420 wire-bonds are consistent along the tile. High-voltage, ultra-high-speed data links and all electrical services are designed and attached in such a way to produce a precise and lightweight detector (a VELO module weighs only 300 g) and therefore minimise the material in the LHCb acceptance.

Every step in the assembly of a module was followed by checks to ensure that the quality met the requirements. These included: metrology to assess the placement and attachment precision of the active components; mechanical tests to verify the effects of the thermal stress induced by temperature gradients; characterisation of the current-voltage behaviour of the silicon sensors; thermal performance measurements; and electrical tests to check the response of the pixel matrix. The results were then uploaded to a database, both to keep a record of all the measurements carried out and to run tests that assign a grade for each module. This allowed for continuous cross-checks between the two assembly sites. To quantify the effectiveness of the cooling design, the change in temperature on each ASIC as a function of the power consumption was measured. The LHCb modules have demonstrated thermal-figure-of-merit values as low as 2–3 K cm2 W–1. This performance surpasses what is possible with, for example, mono-phase microchannel cooling or integrated-pipe solutions.

The delicate VELO modules are mounted onto two precision-machined bases, each housed within a hood (one for each side) that provides isolation from the atmosphere. The complex monolithic hoods were machined from one-tonne billets of aluminium to provide the vacuum tightness and the mechanical performance required. The hood and base system is also articulated to allow the detector to be retracted during injection and to be centred accurately around the collision point during stable beams. Pipes and cables for the electrical and cooling services are designed to absorb the approximately 3 cm motion of each VELO half without transferring any force to the modules, to be radiation tolerant, and to survive flexing thousands of times.

Following the completion of each detector half, performance measurements of each module were compared with those taken at the production sites. Further tests ensured there are no leaks in the high-pressure cooling system or the vacuum volumes, in addition to safety checks that guarantee the long-term performance of the detector. A final set of measurements checks the alignment of the detector along the beam direction, which is extremely difficult once the VELO is installed. Before installation, the detectors are cooled close to their –30°C operating temperature and the position of the tips of the modules measured with a precision of 5 µm. Once complete, each half-tonne detector half is packed for transport into a frame designed to damp-out and monitor vibrations during its 1400 km journey by road from Liverpool to CERN.

RF boxes

One of the most intriguing technological challenges of the VELO upgrade was the design and manufacture of the RF boxes that separate the two detector halves from the primary beam vacuum, shielding the sensitive detectors from RF radiation generated by the beams and guiding the beam mirror currents to minimise wake-fields. The sides of the boxes facing the beams need to be as thin as possible to minimise the impact of particle scattering, yet at the same time they must be vacuum-tight. A further challenge was to design the structures such that they do not touch the silicon sensors even under pressure differences. Whereas the RF boxes of LHCb’s previous VELO were made from 300 μm-thick hot-pressed deformed sheets of aluminium foils welded together, the more complicated layout of the new VELO required them to be machined from solid blocks of small grain-sized forged aluminium. This highly specialised procedure was developed and carried out at Nikhef using a precision five-axis milling machine (see “RF boxes” image).

The VELO upgrade reflects the dedication and work of more than 150 people at 13 institutes over many years

In early prototypes, micro-enclosures led to small vacuum leaks when machining thin layers. A 3D forging technique, performed by block manufacturer Loire Industrie (France), reduced the porosity of the casts sufficiently to eliminate this problem. To form the very thin sides of a box, the inside of the block was milled first. It was then positioned on an aluminium mould. The 1 mm space between box and mould was filled with heated liquid wax, which forms a strong and stable bond at room temperature. The remaining material was then machined until a sturdy flange and box with a wall about 250 μm thick remained, or just over 1% of the original 325 kg block. To further minimise the thickness in the region closest to the beams, a procedure was developed at CERN to remove more material with a chemical agent, leaving a final wall with a thickness between 150 and 200 μm. The final step was the application of a Torlon coating on the inside for electrical insulation to the sensors, and a non-evaporable getter coating on the outside to improve the beam vacuum. The two boxes were installed in the vacuum tank in spring 2021, in advance of the insertion of the VELO modules.

Let collisions commence

LHCb’s original VELO played a pivotal role in the experiment’s flavour-physics programme. This includes the 2019 discovery of CP violation in the charm sector, numerous matter–antimatter asymmetry measurements and rare-decay searches, and the recent hints of lepton non-universality in B decays. The upgraded VELO detector – in conjunction with the new software trigger, the RICH and SciFi detectors, and other upgrades – will extend LHCb’s capabilities to search for physics beyond the SM. It will remain in place for the start of High-Luminosity LHC operations in Run 4, contributing to the full exploitation of the LHC’s physics potential.

Proposed 15 years ago, with a technical design report published in 2013 and full approval the following year, the VELO upgrade reflects the dedication and work of more than 150 people at 13 institutes over many years. The device is now in final construction. One half is installed and is undergoing commissioning in LHCb, while the other is being assembled, and will be delivered to CERN for installation during a dedicated machine stop during May. The assembly and installation has been made considerably more challenging by COVID-19-related travel and working restrictions, with final efforts taking place around the clock to meet the tight LHC schedule. Everyone in the LHCb collaboration is therefore looking forward to seeing the first data from the new detectors and continuing the success of the LHC’s world-leading flavour-physics programme.”