“ARPA-E program awards Laboratory-led materials project $3.1 million; Laboratory partners on two other projects.

The promise of fusion – a potentially game-changing source of low-cost, abundant energy – is constrained by a number of challenges, central among them the lack of materials that can withstand the extreme environments created in fusion reactions. Now $3.1 million in funding from the Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E) OPEN 2021 program will fuel a Los Alamos National Laboratory project to develop novel, tungsten-based alloys that can be used in fusion reactors. The material’s unique design and fabrication potential means that the future of fusion power might be closer than ever before.

“In fusion, the generation of energy is typically not the main problem,” said Osman El Atwani, materials scientist with the Lab’s Materials Science in Radiation and Dynamics Extremes group and the project’s principal investigator. “The challenge of fusion is finding materials that can accept these conditions. Currently, no material can actually stay in an acceptable condition in a fusion reaction. This project aims to develop the first materials capable of serving as plasma-facing components in fusion reactors.”

Unique materials for uniquely extreme environments

El Atwani’s project seeks to design and develop novel, tungsten-based, high-entropy alloys (HEAs) for performance in plasma-facing components (PFCs). The plasma in a fusion reaction burns hotter than the temperature of the sun. That means that PFCs must maintain their thermomechanical properties and radiation resistance under extreme heat fluxes and radiation environments that could induce significant structural and mechanical property changes.

An HEA enlists four or more principal elements, representing a radical departure from traditional alloy design, which involves a single principal element with small additions of alloying elements chosen to achieve specific properties. Tungsten-based HEAs for high-temperature applications possess high melting temperatures – thousands of degrees – and have superior mechanical properties at those temperatures compared to pure tungsten or to nickel-based superalloys.

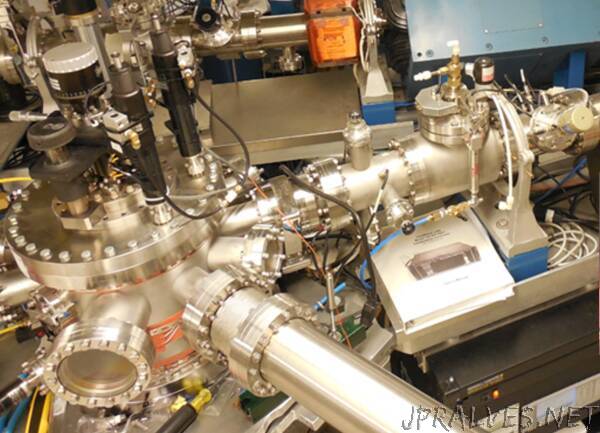

The other prong of the research team’s strategy for materials development is to employ HEAs in nanocrystalline forms. Compared to a coarser grain, the nanocrystalline microstructure adds surface area to the material, increasing strength and radiation resistance. El Atwani and project members tested a promising material at the IVEM-Tandem facility at Argonne National Laboratory and the Lab’s Ion Beams Materials Laboratory. Findings published in the journal Scientific Advances suggest the HEAs are the “ideal structural materials for applications requiring extreme irradiation conditions.” The ARPA-E funding complements an existing pilot program awarded to El Atwani by the DOE Fusion Energy Sciences program to make nanocrystalline tungsten alloy in bulk form.

Ramping up development at the scale for success

Having demonstrated the promise of tungsten-based, nanocrystalline HEAs at lab-scale, the research team intends to aggressively expand alloy optimization, property characterization efforts and radiation testing under reactor-relevant conditions at Los Alamos. The University of Wisconsin-Madison, a partner institution, will refine the additive manufacturing process that can scale up the fabrication of the PFCs, guided by simulation and modeling at Los Alamos and at the third partner institution, Clemson University, as the team works through the many possible combinations of principle elements in HEAs to find the most suitable material. The fourth partner, the Massachusetts Institute of Technology, will perform ultra-rapid radiation stability testing for further down-selection of HEA compositions before final HEA selections are performed at Los Alamos.

The scope of the project’s goals – from design and development to manufacturing – reflects the urgent need to ramp up the production of clean energy technology, providing much-needed answers for energy security and offering a boost for the economy.

“The path toward fusion power generation will remain slow if better material solutions are not achieved,” said El Atwani. “Successful design and development of PFCs has the potential to make fusion power generation cost-effective, economically predictable and more attractive to investors.”

ARPA-E Partnerships

Los Alamos National Laboratory researchers are also partnering on two other projects funded in the ARPA-E OPEN 2021 program.

Led by Carnegie Mellon University, a team is working on ionomer-free electrodes to support improvements in polymer electrolyte membrane fuel cell technology. The technology would eliminate the ionomer from the electrode in a fuel cell, improving the chemical reaction and enabling the deployment of low-cost, high-efficiency fuel cells. Jacob Spendelow and Xiaojing Wang, members of the Materials Synthesis and Integrated Technologies group at the Laboratory, are a part of the project team that could electrify the nation’s driving.

Veir, a company based in Massachusetts, is working to develop high-current 10 kV power lines. The project uses superconducting lines to carry more power on shorter towers and in narrower rights-of-way. Doan Nguyen, researcher at the Laboratory’s National High Magnetic Field Laboratory, is a part of the project that can improve the delivery of renewable energy and support the increased electrification demand from end users.

LA-UR-22-21347”