“New method overcomes the drawbacks typically associated with data-driven methods such as data bias and poor availability

Building prediction models for high entropy alloys (HEAs) using material data is challenging, as datasets are often lacking or heavily biased. Now, researchers have developed a new evidence-based recommender system that determines various element combinations for potential HEAs. Unlike conventional data-driven techniques, this method has the added ability to recommend potential HEA candidates from limited amounts of experimental data. Their method can facilitate the development of alloys that have applications as advanced functional materials.

High entropy alloys (HEAs) have desirable physical and chemical properties such as a high tensile strength, and corrosion and oxidation resistance, which make them suitable for a wide range of applications. HEAs are a recent development and their synthesis methods are an area of active research. But before these alloys can be synthesized, it is necessary to predict the various element combinations that would result in an HEA, in order to expedite and reduce the cost of materials research. One of the methods of doing this is by the inductive approach.

The inductive method relies on theory-derived “descriptors” and parameters fitted from experimental data to represent an alloy of a particular element combination and predict their formation. Being data-dependent, this method is only as good as the data. However, experimental data regarding HEA formation is often biased. Additionally, different datasets might not be directly comparable for integration, making the inductive approach challenging and mathematically difficult.

These drawbacks have led researchers to develop a novel evidence-based material recommender system (ERS) that can predict the formation of HEA without the need for material descriptors. In a collaborative work published in Nature Computational Science, researchers from Japan Advanced Institute of Science and Technology (JAIST), National Institute for Materials Science, Japan, National Institute of Advanced Industrial Science and Technology, Japan, HPC SYSTEMS Inc., Japan, and Université de technologie de Compiègne, France introduced a method that rationally transforms materials data into evidence about similarities between material compositions, and combines this evidence to draw conclusions about the properties of new materials.

The research team consisted of Professor Hieu-Chi Dam from JAIST and his colleagues, Professor Van-Nam Huynh, Assistant Professor Duong-Nguyen Nguyen, and Minh-Quyet Ha, PhD student (JAIST); Dr. Takahiro Nagata, Dr. Toyohiro Chikyow, and Dr. Hiori Kino (National Institute for Materials Science, Japan); Dr. Takashi Miyake, (National Institute of Advanced Industrial Science and Technology, Japan); Dr. Viet-Cuong Nguyen (HPC SYSTEMS Inc., Japan); and Professor Thierry Denœux (Université de technologie de Compiègne, France).

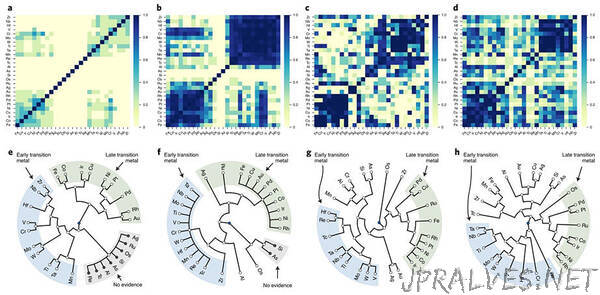

Regarding their novel approach to this issue, Prof. Hieu-Chi Dam elaborates: “We developed a data-driven materials development system that uses the theory of evidence to collect reasonable evidence for the composition of potential materials from multiple data sources, i.e., clues that indicate the possibility of the existence of unknown compositions, and to propose the composition of new materials based on this evidence.” The basis of their method is as follows: elements in existing alloys are initially substituted with chemically similar counterparts. The newly substituted alloys are considered as candidates. Then, the collected evidence regarding the similarity between material composition is used to draw conclusions about these candidates. Finally, the newly substituted alloys are ranked to recommend a potential HEA.

The researchers used their method to recommend Fe-Co-based HEAs as these have potential applications in next-generation high power devices. Out of all possible combinations of elements, their method recommended an alloy consisting of iron, manganese, cobalt, and nickel (FeMnCoNi) as the most probable HEA. Using this information as a basis, the researchers successfully synthesized the Fe0.25Co0.25 Mn0.25Ni0.25 alloy, confirming the validity of their method.

The newly developed method is a breakthrough and paves the way forward to synthesize a wide variety of materials without the need for large and consistence datasets of material properties as Prof. Dam explains, “Instead of forcibly merging data from multiple datasets, our system rationally considers each dataset as a source of evidence and combines the evidence to reasonably draw the final conclusions for recommending HEA, where the uncertainty can be quantitatively evaluated.”

While furthering research on functional materials, the findings of Prof. Dam and his team are also a noteworthy contribution to the field of computational science and artificial intelligence as they allow the quantitative measurement of uncertainty in decision making in a data-driven manner.”