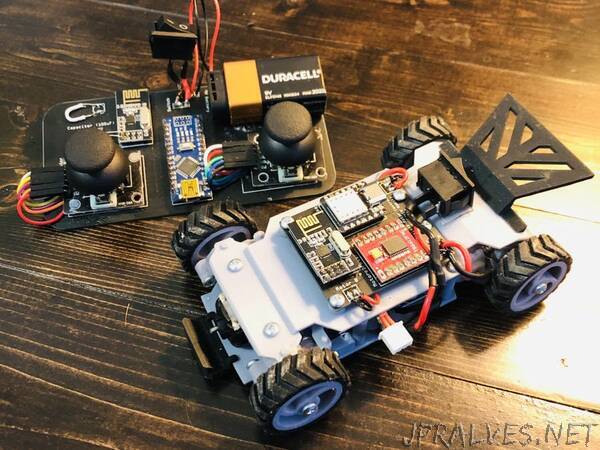

“Version 1 of my design for an RC Car using an Arduino Nano and a Seeeduino XIAO. I call this RC_Car_RP.

A lot can happen in a few weeks with enough resin and persistence. The first version of my 3D printed Arduino-based RC car is complete. This project started when I hacked my kid’s broken RC Car. I have now created RC_Car_RP (Rack And Pinion). All of the files for this project can be found on Github here. A bill of materials and build video are to come.

#define projectObjectives;

- A small footprint – My benchmark is to be able to print the car on an Original Elegoo Mars Resin bed, ideally with few (or no) supports.

- Simple design – I am trying to minimize the number of parts.

- Highly adaptable parts and electronics (Arduino) – My original prototype fit on one single 5x7cm protoboard. The next model, RC_Car_SS, will include servo steering.

- Easy to Build – To make wiring easier and further decrease size, I created the RC_Car_RP PCB.

#define projectConstraints;

- Car body width will not be less than 55 mm (so as to accept Seeeduino PCB, 5×7 protoboards, Double Feather setups, and Nano breakouts).

- Car body length will not be less than 110 mm (gives room for steering motor, 130 style drive motor, and enough space to accept all the boards I just mentioned regarding width).

- All components must individually fit in the dimensions of the original Elegoo Mars Resin Bed when printed flat (max = 68 mm x 120 mm). Note that the max Z height of the Mars is 150 mm, but we want the option to print as flat as possible and will favor that orientation to decrease materials, time required and print failures. (Although, I acknowledge we are actually shooting to print with supports at about a 20 to 30 degree angle, which will decrease deformation.)”