“Imagine a child playing with a magnifying glass – focusing the sunlight down into a single, heated ring of light. That light is the basis of solar energy.

A team of researchers led by Dr. Christi Madsen, professor in the Department of Electrical and Computer Engineering at Texas A&M University, is fabricating new solar technology. Their project, funded by the Department of Energy’s Advanced Research Projects Agency-Energy, laid the groundwork for the future of solar concentrators using advanced photovoltaics (PV) cells.

At the heart of solar panels are PV cells that absorb light and transform optical energy into clean electricity. Solar energy begins like a child holding a magnifying glass: With components called concentrators, the veritable magnifying glass, focusing light into a single beam. That beam is channeled through waveguides – tunnel-like paths for photons to move down – that all lead to the PV cell.

Originally they aimed to both increase efficiency and shrink the large volume box-like concentrator array down to something akin to the residential solar panels found on house rooftops, but the team found their focus in fabrication.

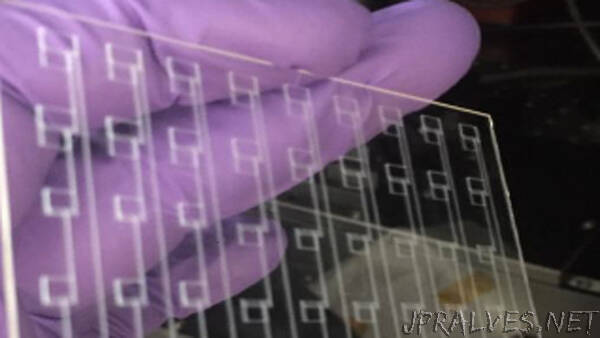

“We wanted to use the purest glass possible, to get all the light – get all those photons – to the PV cell,” said Madsen. “So we started pursuing this technique where we would use a femtosecond laser and would shine the laser on an area of a glass plate that we would then put into an etch bath and remove just that section.”

In addition to being able to cut out various shapes and angles that would help reflect and guide the light toward the PV cell, the fabrication method is also able to utilize a laser to smooth the glass. Smoothness is key to efficiently harvesting photons.

“We set a target of very high efficiencies to get everything that the sun gave us out to the photovoltaic cell,” said Madsen. “The way we were thinking about it was that every photon that comes in from the sunlight, we want to get through our structure. If the surface is rough, then you’re going to scatter light, so it’s not going to reach the PV cell.”

The less photons that make it to the PV cell, the less electricity that is produced, and thus, the lower the efficiency of the solar panel.

“It’s all about getting the ultimate efficiency that we can get from the sunlight,” said Madsen. “So instead of playing with magnifying glasses, we’re producing electricity.”

Looking forward, Madsen is setting her sights on the future of solar technology and optical devices. The fabrication techniques her team is continuing to develop has the potential to create glass structures of all shapes that will be useful to both research, energy and consumers.

“I think (this method is) going to make devices that will eventually make it into consumer products. But right now, we’re just starting to flesh it out,” said Madsen. “My goal is to get the fabrication and processes more repeatable and finer tuned. We really want to be able to make interesting optical devices and this is a nice way to do it.””