“KIT’s Startup otego GmbH Has Developed “oTEG,“ the First Commercial Printed Thermoelectric Generator Worldwide

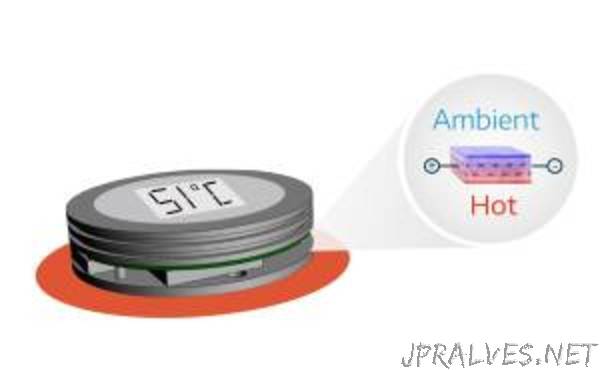

Power plants not larger than a sugar cube that can be used for both domestic and industry purposes: Thermoelectric generators (TEG) convert even small ambient temperature differences into electrical energy. otego GmbH, a spinoff of Karlsruhe Institute of Technology (KIT), has now commercialized the first electronic component of its kind: “oTEG” will be presented by the developers at the Hannover Messe from April 23 to 27, 2018.

The team of otego makes thermoelectdric generators (TEG) fit for the mass market by using novel materials and large-scale production processes. Production of a prototype series is about to start this year. The “oTEG” innovative energy converter is suited for a large range of applications in the areas of Industry 4.0 and Smart Homes. Similar to solar cells that convert light into electrical energy, TEGs can extract electrical power from the ambient heat and, in this way, ensure continuous supply. “Various sensors, evaluation electronics, and wireless systems can be operated without a battery: From simple products, such as a wireless data tracker, to distributed sensor nodes of industrial facilities to future electronic thermostats of radiators,” says Frederick Lessmann, one of the founders of the company. TEGs not only are an ideal energy source for comfort applications in the domestic environment, they can also be used for the power supply of a number of autonomous industry sensors in larger facilities. Polymer materials make the oTEG mechanical flexible and insensitive to impacts and vibrations. It can be operated for a longer term without any maintenance being required. Heavy metals are not needed at all, consumption of natural resources is reduced.

[Textfeld: Thermoelectric generator made by otego – as small as a sugar cube. (Figure: otego GmbH)] Conversion of energy from ambient heat is based on the Seebeck effect: The temperature gradient in the thermoelectric semiconductor material induces an electric voltage. When combined with another semiconductor material generating a complementary voltage, if possible, the potential of this “thermocouple” can be used as a source of voltage for small consumers. In oTEG, thousands of these thermocouples are connected in series. The generated voltage in the single-digit volt range is sufficient to operate microelectronic circuits. The difference of the oTEGs lies in the self-developed production process: “We print the electronic conducting paths onto extremely thin plastic foils – the time needed corresponds to about the time needed for printing a newspaper. Then, we use our special automated origami folding method to bring these printed foils into a compact form. In the past years, we intensively worked on implementing this method on the industrial scale for rapid production at low costs,” Lessmann says.

In the second half of this year, otego plans to produce a prototype series to realize concrete product applications with company partners. The startup does not only want to integrate generators in existing systems, but also enters new ground. Whereas battery storage systems or supply cables have been indispensable so far, the autonomous and maintenance-free oTEGs enable entirely new product approaches.”