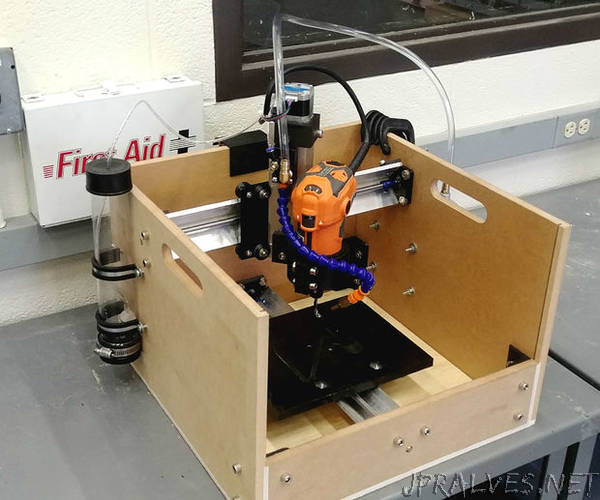

“Intro:This idea stems from attempts at cutting aluminum at more aggressive rates which often led to melted aluminum on an overheated bit. This coolant system allows for both increased feed/cut depths and prolonged cutting tool life. The design aimed to keep the mill portable by mounting all components to the mill itself and using an air pump instead of depending on an air compressor (with the pump running significantly quieter). Designed for the Sienci Mill One, it could easily be adapted for most compact CNC mills.

The design doesn’t require any special skills beyond what would be needed to assemble the mill to begin with, and the ability to drill. Minus the pump and nozzle/regulator block, most of the materials used can be found at any local hardware store. Polycarb tube was chosen to see the level of coolant in the system, but this can just as easily be replaced with PVC pipe. It is highly recommend that the inside of the mill be coated with some form of sealant to protect the MDF walls from moisture.”