“This project outperforms two previous hotplates in both electrical and mechanical aspects. It has two separate boards—the coil board and the driver board—that are joined together by 40mm-long PCB standoffs.

This project is powered by an XIAO ESP32 C3 MCU, which in turn controls an NPN BJT, which in turn controls an IRFZ44N Mosfet, which drives the coil.

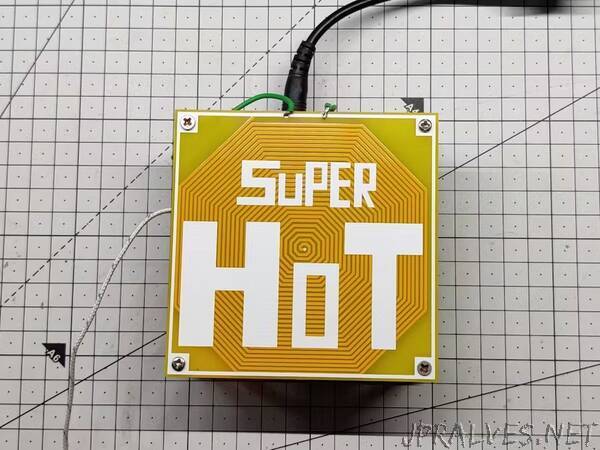

About the project’s heating element, the coil board, which has tracks arranged in an octagon arrangement on both its top and bottom sides, each coil has its own resistance, and when a specific voltage is applied, it heats up, making a DIY element constructed on the FR4 PCB.

The utilization of two separate boards is one of the project’s best features. As the TG rating of FR4 is below 140 °C and we are heating the board above that temperature, the hotplate coils generally degrade and then become damaged after 10–15 cycles. Fortunately, replacing the damaged coil with a new one is simple and doesn’t require making major changes to the driver board.

Let’s explore the project’s construction process.

Following were the materials used in this build-

- Custom PCB- Provided by Seeed Studio (Both Boards)

- XIAO ESP32 C3 MCU

- AMS1117 5V

- 10uF 1206 CAP

- 1uF 1206 CAP

- 1K Ohms 1206 Resistor

- 10K Ohms 0805 Resistor

- RED LEDs 0603

- BLUE LED 0805

- DC Barrel Jack Horizontal

- 40mm Length M3 PCB Standoffs

- IRFZ44N Mosfet

- BC547 Transistor SOT23-3

- 12V 4A Power Source

- Multimeter with TEMP Probe”