“Understanding how short-circuits occur in solid-state batteries could extend their lifespan

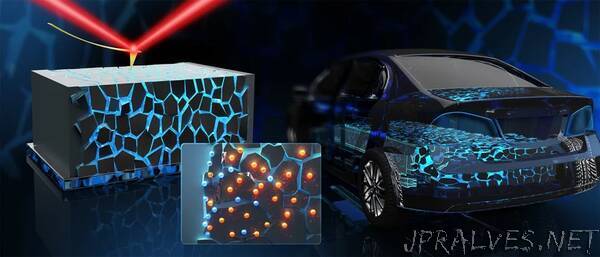

They could be the next generation of battery: so-called ‘solid-state’ batteries. They’re made entirely of solid materials and have no liquid medium between their poles, as today’s batteries do. These types of batteries could extend the range of electric cars and make them safer, as they can store more electricity and are less flammable. So far, however, they have suffered from limited lifetimes. A team from the Max Planck Institute for Polymer Research has studied the processes that reduce the lifespans. Its findings could help build longer-lasting solid-state batteries.

Whether it is an e-car, a mobile phone, or a cordless screwdriver, rechargeable batteries are used in many devices. And as electric vehicles become more ubiquitous, so the demand will increase. Occasionally, however, the lithium batteries commonly used in electric cars and mobile phones have burst into flames unexpectedly. This is why some mobile phones are not allowed on board of aircraft. In addition, common rechargeable batteries are sensitive to shocks and impacts.

Solid-state batteries, or solid-state accumulators as they are also called, could provide a remedy to this. These dispense with the liquid electrolyte that conducts the current between the poles in the battery and work instead with a solid material, for example a lithium-containing ceramic ion conductor. This makes them non-flammable, mechanically robust and insensitive to temperature fluctuations. In addition, they have a larger storage capacity and are easy to miniaturise. This not only makes them interesting for use in electric cars but also for new applications in which particularly small batteries are required, for example in microrobots.

Stalactite and stalagmite formation in the battery?

So far, however, the lifespan of lithium solid-state batteries has been fairly short. This is because lithium dendrites grow between the positive and negative terminals of the battery during each charging process. These branched, tree-like metal formations short-circuit the battery after a few charge and discharge cycles. It has long been unclear how exactly the dendrites are formed. That is why a team led by Rüdiger Berger, a research group at the Max Planck Institute for Polymer Research, has now investigated the processes using a special microscopy method. The researchers were primarily interested in the question of where the lithium dendrites form. Do stalactites form at both poles, similar to the way stalactites grow from the ceiling and stalagmites from the floor in a limestone cave, until they meet in the middle? Or do the dendrites only form at one pole? Are there possibly special places in the battery that serve as nuclei for dendritic growth?

During the study, Rüdiger Berger’s team paid particular attention to the grain boundaries in the ceramic solid-state electrolyte. The atoms here arrange themselves in a regular manner in the same way as with salts or metals. They form crystals – not a single one, however, but many small crystal grains that are slightly offset from one another causing grain boundaries to form between them. The researchers use Kelvin probe force microscopy in which a sharp tip scans the surface to visualise what happens at the grain boundaries during charging. “When the solid-state battery is charged, Kelvin probe force microscopy shows us that electrons accumulate along the grain boundaries – especially near the negative pole,” says Chao Zhu, a PhD student in Rüdiger Berger’s team.

Dendrites sprout at electron accumulations

The accumulated electrons can reduce lithium ions travelling through the solid electrolyte to metallic lithium. This causes lithium to settle, and a lithium dendrite is formed. With each charging process, the dendrite continues to grow until it finally short-circuits the poles. Since the electron density increases mainly at the minus pole, the dendrites also only began to grow there.

The researchers hope that gaining a precise understanding of how the harmful metal trees grow in a solid-state battery will help to stop or at least contain their growth. One starting point, for example, could be the production of the solid-state electrolyte: “It may be helpful to make the path along the grain boundaries as long as possible,” says Rüdiger Berger. “This could be done in a similar way to a brick wall.” To do so, the crystal grains of the electrolyte would have to be grown in a way that gives them short and long sides like bricks. The longer side would then have to be perpendicular to the direct path between the electrodes. So far, however, it is still unclear whether and how crystal formation in solid-state electrolytes can be controlled in this manner and whether the lifespan of solid-state batteries can actually be extended in this way. This will have to be investigated in further studies. If these are successful, solid-state batteries would have a good chance of replacing the sensitive conventional lithium batteries.”