“High-frequency light is useful. The higher the frequency of light, the shorter its wavelength—and the shorter the wavelength, the smaller the objects and details the light can be used to see.

So violet light can show you smaller details than red light, for example, because it has a shorter wavelength. But to see really, really small things—down to the scale of billionths of a meter, thousands of times less than the width of a human hair—to see those things, you need extreme ultraviolet light (and a good microscope).

Extreme ultraviolet light, with wavelengths between 10 and 120 nanometers, has many applications in medical imaging, studying biological objects, and deciphering the fine details of computer chips during their manufacture. However, producing small and affordable sources of this light has been very challenging.

We have found a way to make nanoparticles of a common semiconductor material emit light with a frequency up to seven times higher than the frequency of light sent to it. We generated blue-violet light from infrared light, and it will be possible to generate extreme ultraviolet light from red light with the same principles. Our research, carried out with colleagues from the University of Brescia, the University of Arizona and Korea University, is published in Science Advances.

The power of harmonics

Our system starts out with an ordinary laser that produces long-wavelength infrared light. This is called the pump laser, and there’s nothing special about it—such lasers are commercially available, and they can be compact and affordable.

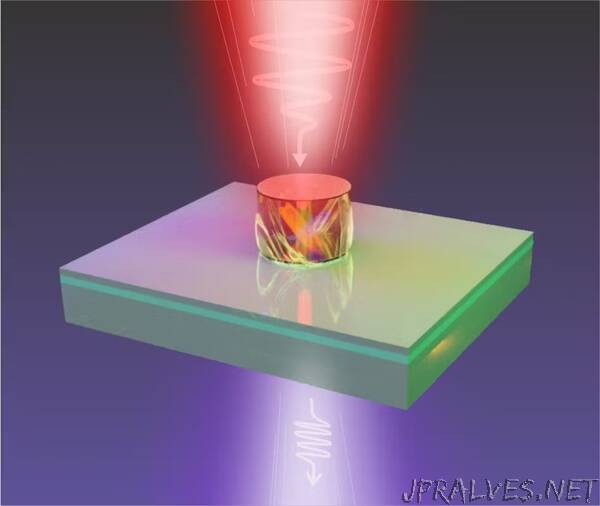

But next we fire short pulses of light from this laser at a specially engineered nanoparticle of a material called aluminum gallium arsenide, and that’s where things get interesting.

The nanoparticle absorbs energy from the laser pulses, and then emits its own burst of light. By carefully engineering the size and shape of the nanoparticle, we can create powerful resonances to amplify certain harmonics of the emitted light.

What does that mean, exactly? Well, we can make a useful analogy with sound.

When you pluck a string on a guitar, it vibrates with what’s called its fundamental frequency—which makes the main note you hear—plus small amounts of higher frequencies called harmonics, which are multiples of the fundamental frequency. The body of the guitar is designed to produce resonances that amplify some of these harmonics and dampen others, creating the overall sound you hear.

Both light and sound share similarities in their physics—these are both propagating waves (acoustic waves in the case of sound, and electromagnetic waves in the case of light).

In our light source, the pump laser is like the main note of the string, and the nanoparticles are like the guitar body. Except what’s special about the nanoparticles is that they massively amplify those higher harmonics of the pump laser, producing light with a higher frequency (up to seven times higher in our case, and a wavelength correspondingly seven times shorter).

What it’s good for

This technology allows us to create new sources of light in parts of the electromagnetic spectrum such as the extreme ultraviolet, where there are no natural sources of light and where current engineered sources are too large or too expensive.

Conventional microscopes using visible light can only study objects down to a size of about a ten-millionth of a meter. The resolution is limited by the wavelength of light: violet light has the wavelength of about 400 nanometers (one nanometre is one billionth of a meter).

But there are plenty of applications, such as biological imaging and electronics manufacturing, where being able to see down to a billionth of a meter or so would be a huge help.

At present, to see at those scales you need “super-resolution” microscopy, which lets you see details smaller than the wavelength of the light you are using, or electron microscopes, which do not use light at all and create image using a flux of electrons. However, such methods are quite slow and expensive.

To understand the advantages of a light source like ours, consider computer chips: they are made of very tiny components with feature sizes almost as small as a billionth of a meter. During the production process, it would be useful for manufacturers to use extreme ultraviolet light to monitor the process in real time.

This would save resources and time on bad batches of chips. The scale of the industry is such that even a 1% increase in chip yields could save billions of dollars each year.

In future, nanoparticles like ours could be used to produce tiny, inexpensive sources of extreme ultraviolet light, illuminating the world of extremely small things.”