“Using an ultrafast laser direct writing method, researchers arrange 3D voxels in glass to precisely direct light for various applications

Modern-day technologies like optical computing, integrated photonics, and digital holography require light signals to be manipulated in three dimensions. To achieve this, it is necessary to be able to shape and guide the flow of light according to its desired application. Given that light flow within a medium is governed by the refractive index, specific tailoring of the refractive index is needed to realize control of the light path within the medium.

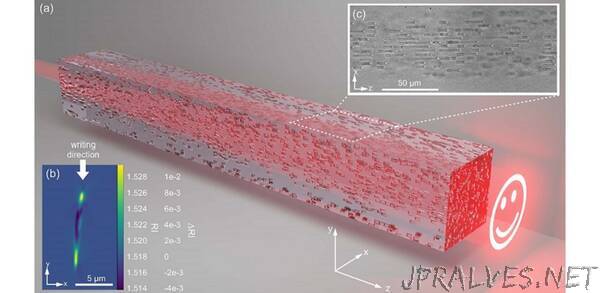

To this end, scientists have developed what are called “aperiodic photonic volume elements” (APVEs), microscopic voxels with specific refractive indices located at predefined positions to direct the flow of light in a controlled manner. However, sculpting these elements requires a high degree of precision, and most light-shaping materials are limited to 2D configurations or end up degrading the output light beam profile.

In a recent study published in Advanced Photonics Nexus (APNexus), researchers led by Alexander Jesacher from the Medical University of Innsbruck in Austria proposed a simple approach to fabricating highly precise APVEs for a range of applications. The method uses a technique called “direct laser writing” for the 3D arrangement of voxels of specific refractive indices inside borosilicate glass.

In their study, the researchers designed an algorithm that stimulates the flow of light through a medium to determine the optimum placement of voxels for achieving the necessary precision. Based on this, they were able to generate between 154,000 and 308,000 voxels, each occupying a volume of approximately 1.75 µm × 7.5 µm × 10 µm, within just 20 minutes. Additionally, they used dynamic wavefront control to compensate for any spherical aberration (beam profile distortion) during the focusing of laser on the substrate. This ensured the consistency of each voxel profile at all depths within the medium.

The team developed three types of APVEs to demonstrate the applicability of the method: an intensity shaper for controlling the intensity distribution of the input beam, an RGB multiplexer that manipulated the transmission of the red-green-blue (RGB) spectra of the input beam, and a Hermite–Gaussian (HG) mode sorter to enhance data transfer speeds.

The team used the intensity shaper to convert a Gaussian beam into a microscopic smiley-shaped light distribution, followed by the multiplexer to represent different parts of the smiley distribution in different colors, and finally the HG mode sorter to convert multiple Gaussian mode inputs delivered by the optical fibers into HG modes. In all cases, the devices were able to transmit the input signal without significant loss and achieved a record-high diffraction efficiency of up to 80 percent, setting a new benchmark for the standard of APVEs.

“The results reported in this paper greatly advance the field of ultrafast laser direct writing. The novel method could open doors to an ideal low-cost platform for a rapid prototyping of highly integrated 3D light shapers,” says APNexus Editorial Board Member Paulina Segovia-Olvera of the Center for Scientific Research and Higher Education at Ensenada (CICESE). “The demonstration of a solid method for producing consistent, reproducible, and reliable APVEs not only adds to the current knowledge in the field but also enables new avenues in applied photonics,” she adds.

The method, in addition to its simplicity, low cost, and high precision, can probably also be extended to other substrates, including nonlinear materials. “The flexibility of our method could make it viable for designing a wide range of 3D devices for applications in information transport, optical computing, multimode fiber imaging, nonlinear photonics, and quantum optics,” concludes Jesacher.

Read the Gold Open Access article by N. Barré et al., “Direct laser written aperiodic photonic volume elements for complex light shaping with high efficiency: inverse design and fabrication,” Adv. Photon. Nexus 2(3) 036006 (2023), doi 10.1117/1.APN.2.3.036006”