“Since the 1940s, engineers have used a common design language — a set of definitions, symbols and practices — to draft engineering drawings that can serve as clear manufacturing blueprints or inspection checklists.

While this system still works well for many traditional manufacturing methods, it has not equipped engineers to produce clear and consistent design documents for additive manufacturing, commonly called 3D printing. And the absence of standard methods of communication leaves room for information about 3D-printing designs to be lost in translation.

This week the American Society of Mechanical Engineers (ASME) published an updated standard — based in large part on research by the National Institute of Standards and Technology (NIST) — that includes language specifically for 3D printing. ASME’s standard, titled Y14.46 Product Definition for Additive Manufacturing, identifies important features unique to 3D printing and outlines how they should be documented.

The guidance could help engineers from a broad array of industries communicate to manufacturers, product inspectors and others more effectively. Its widespread adoption could clear a persistent roadblock to the application of 3D printing at a larger scale, unlocking the environmental and economic benefits associated with the technology.

“The industry is in a digital transformation right now, moving away from physical 2D drawings, and additive manufacturing is one of the catalysts since it requires digital 3D models,” said Fredric Constantino, an ASME project engineering adviser. “And if you’re working on one of those models, this standard will guide you in making it understandable to both 3D printers and other people.”

With subtractive manufacturing, a common production method, machines carve out parts from blocks of raw material according to instructions, which can be outlined in a digital or physical 2D drawing. By contrast, additively manufactured products take shape from the ground up, as printers churn out one layer at a time, fusing them into a predetermined shape that can only be dictated by a 3D model.

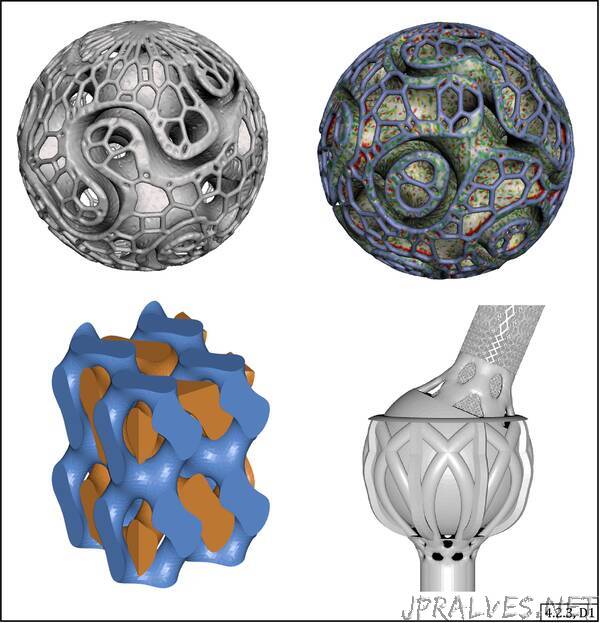

In addition to producing less waste than subtractive methods, 3D printing also allows for designs of higher complexity, such as those that are not completely solid, but partially hollow, filled with a meshwork that could come in many forms.

“Additive manufacturing has opened the door to a lot of unique design opportunities for engineers, but that freedom also creates challenges in communicating complex designs,” said NIST mechanical engineer Paul Witherell.

The lack of a consensus on how to convey aspects of a product related to 3D printing’s distinct capabilities has muddled communication between different organizations and created a barrier to more widespread use of the technology.

ASME responded to this roadblock in 2014, forming a committee of several dozen engineers from industry, academia and the federal government. The group, co-led by Witherell through 2019, sought to produce a uniform approach for defining 3D-printed products.

“We weren’t looking for ad hoc solutions. We were looking for solutions that could be standardized and implemented by the community to address these challenges with communication,” Witherell said. “We already know we can make good parts with additive manufacturing. Now the goal is to make lots of parts with additive manufacturing, and this is a necessary step.”

The committee developed the standard over the course of several years, drawing on input from 3D-printing experts and NIST research. They also incorporated feedback on a draft version of the standard released in 2017.

With the new guidance, the group introduces concepts to address not only the nuances of 3D-printing designs themselves, such as their potentially intricate internal geometry, but the peculiarities of the printing process. Factors, including the orientation of a print and whether temporary structural supports are printed, can influence the strength, durability and other properties of the end product.

Since printers need digital product information to be presented in a particular way, the guidance also includes a section on how to package 3D-model-based data so that it’s machine readable.

Designers are meant to reference the new standard along with several previously established standards, which cover basic design considerations that are relevant to a broad array of manufacturing methods.

3D printing holds several clear advantages over more well-established manufacturing methods, but it has not been implemented nearly to the same degree. One reason for this has been the lack of a fundamental way to get design ideas across — a gap now filled due to the efforts of ASME and NIST.

If adopted by major players in manufacturing, the standard could improve communication for 3D printing, potentially making for a more sustainable and efficient manufacturing industry in the future. However, expanding the standard along the way will be key.

“Some of ASME’s other standards go 10 years, 20 years without revision, but additive manufacturing is advancing so rapidly. We aim to keep pace by adding to this standard as time goes on,” Constantino said. “We expect it to evolve quickly.””