“Scientists develop a framework based on quantum calculations to solve a long-standing problem in materials science.

Real-life optimization problems are often solved using techniques that borrow concepts from quantum mechanics. In a new study, scientists from Japan apply and compare the performance of such a quantum technique with conventional methods in solving an important quantum problem in materials science, reporting a relatively slower growth in computational cost of the former, making it a potentially superior choice for problem-solving following future technological advancements.

One of the most important classes of problems that all scientists and mathematicians aspire to solve, due to their relevance in both science and real life, are optimization problems. From esoteric computer science puzzles to the more realistic problems of vehicle routing, investment portfolio design, and digital marketing—at the heart of it all lies an optimization problem that needs to be solved.

An appealing technique often used in solving such problems is the technique of “quantum annealing”, a framework that tackles optimization problems by using “quantum tunneling”—a quantum physical phenomenon—to pick out an optimum solution out of several candidate solutions. Ironically, it is in quantum mechanical problems where the technique has found rather scarce application! “Chemists and material scientists, who deal with quantum problems, are mostly unfamiliar with quantum annealing and so do not think to use it. Finding applications of this technique is therefore important for increasing its recognition as a useful method in this domain,” says Prof. Ryo Maezono from Japan Advanced Institute of Science and Technology (JAIST), who specializes in applying information science to the field of materials science.

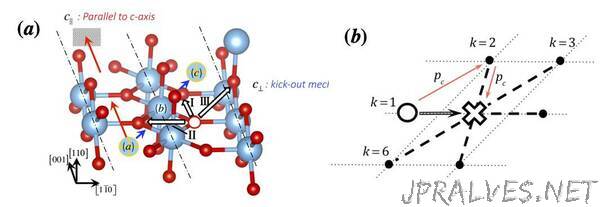

To that end, Prof. Maezono explored, in a recent study published in Scientific Reports, the phenomenon of ionic diffusion in solids, a topic of great interest in both pure and applied materials science, along with his colleagues, Keishu Utimula, a PhD graduate in materials science from JAIST (in 2020) and lead author of the study, Prof. Kenta Hongo, and Prof. Kousuke Nakano, by applying a framework that combined quantum annealing with ab initio calculations, a method that calculates physical properties of materials without relying on experimental data. “While current ab initio techniques can provide information about diffusion path networks of the ions, it is difficult to map that information into useful knowledge of the diffusion coefficient, a practically relevant quantity,” explains Prof. Maezono.

Specifically, the team looked to calculate the “correlation factor”, a key quantity in the diffusion process, and realized that this could be done by framing the process as a routing optimization problem, which is precisely what the quantum annealing framework is designed to solve! Accordingly, scientists calculated the correlation factor for a simple two-dimensional tetragonal lattice, for which they already knew the exact result, using quantum annealing and a variety of other computational techniques and compared their outputs.

While the evaluated correlation factors were consistent with the analytical result for all the methods employed, all the approaches suffered from limitations due to unrealistic computational costs for large system sizes. However, scientists noted that the computational expense for quantum annealing grew much more slowly in a linear fashion compared to the other techniques, which showed rapid exponential growth.

Prof. Maezono is excited by the finding and is confident that, with sufficient technological advancement, quantum annealing would present itself as the best possible choice for solving problems in materials science. “The problem of ion diffusion in solids is of central importance in building smaller batteries with higher capacity or improving the strength of steel. Our work shows that quantum annealing is effective in solving this problem and can expand the scope of materials science as a whole,” he concludes.

This study was funded by Grant-in-Aid for JSPS Research Fellow (18J12653), KAKENHI grant (JP17K17762), a Grant-in-Aid for Scientific Research on Innovative Areas “Mixed Anion” project (JP16H06439) from MEXT, PRESTO (JPMJPR16NA), the Materials research by Information Integration Initiative (MI2I) project of the Support Program for Starting Up Innovation Hub from Japan Science and Technology Agency (JST), MEXT-KAKENHI (17H05478 and 16KK0097), Toyota Motor Corporation, I-O DATA Foundation, the Air Force Office of Scientific Research (AFOSR-AOARD/FA2386-17-1-4049), and MEXT FLAGSHIP2020 (hp170269, hp170220).”