“Researchers at National University of Science and Technology MISIS (NUST MISIS) have managed to develop a unique method to process bulk metallic glasses. According to the authors of the study, they have managed to find processing conditions that significantly improve the quality of this promising material. The research results were published in Journal of Alloys and Compounds.

Metallic glasses (amorphous metals) are materials which, unlike crystalline forms, don’t have a long range atomic order. According to the scientists, this makes the material high-strength, elastic, corrosion resistant; amorphous metals also have other useful properties, due to which they are in demand in instrument making, mechanical engineering, medicine and magneto-electrical engineering.

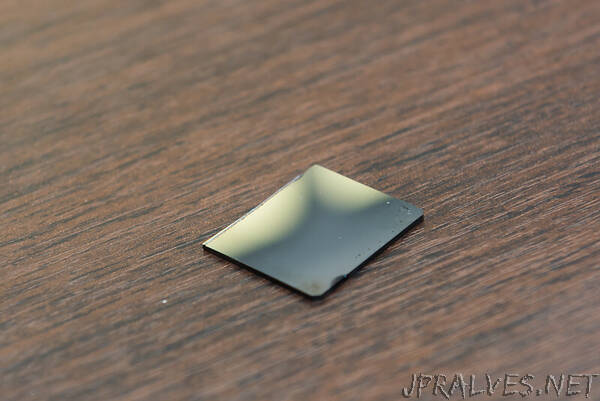

NUST MISIS scientists explained that the material’s brittleness is one of the obstacles to its widespread use. The authors of the study believe that the new method to process metallic glasses will help eliminating this problem. The method was tested on an amorphous Zr-Cu-Fe-Al system alloy.

“Annealing before and after rolling was ‘prohibited’ by the canons of the science of metallic glasses, since this leads to their embrittlement in the absolute majority of cases. The choice of the alloy composition and alloying system helped us bypass this problem: annealing at about 100 degrees below the glass-transition temperature allowed to achieve ductilization of bulk samples and hardening of tape samples without embrittlement,” Professor Dmitry Luzgin, the research supervisor, explained.

According to the scientists, it is the way the original amorphous matrix of the alloy decomposes that affects the resulting material’s characteristics. Different results are achieved depending on the samples’ geometry, bulk or tape.

“For bulk samples, we’ve achieved an increase in tensile plasticity of up to 1.5% at room temperature by dividing a homogeneous amorphous phase into two. For ribbon samples, a 25% increase in hardness has been achieved, which is provided with the separation of secondary-amorphous-phase glassy nanoparticles of about 7 nm with retention of plasticity on bending and compression. This is an unexpected and rather significant result,” Andrey Bazlov, the author of the method, an employee at the Department of Physical Metallurgy of Non-ferrous Metals of NUST MISIS, said.

NUST MISIS scientists explained that the Zr-Cu-Fe-Al system alloy cannot be used as the main structural material due to its high cost; but they believe that the proposed technology can be applied to other amorphous alloys, in particular, titanium.

The new method will simplify the process of imparting the necessary properties to metallic glasses, thereby expanding their scope of application. In the future, the research team wants to use the new technology to produce titanium and other high-quality bulk metallic glasses.”