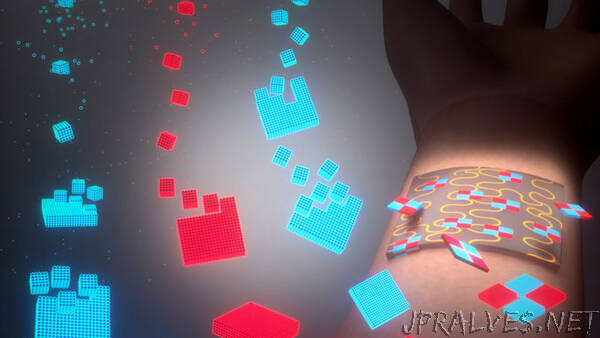

“Materials made from nanoscale particles, ranging in size from a few atoms up to less than one-percent of the width of a human hair, create opportunities to design new functional materials having unique responses to external stimuli, such as light, electrical and magnetic fields and mechanical deformation. Embedding such particles in a “matrix” (referring to a surrounding medium or structure) composed of a different material makes it possible to create nanocomposites that enable new technologies.

The central challenges in developing transformative nanoparticle-based devices have been summarized in an article review co-authored by Tyler Ray, a University of Hawaiʻi at Mānoa engineering professor, and Matthew Begley and Daniel Gianola of UC Santa Barbara’s College of Engineering.

“Bridging functional nanocomposites to robust macroscale devices,” published in a recent issue of SCIENCE, illustrates that a central need for tomorrow’s materials scientists and engineers is to gain sufficient control during processing at multiple size scales. In order to create new devices, synthesized materials must be able to survive, intact, the strong forces that are encountered in manufacturing processes, at size scales from the atomic scale to the human scale.

The review describes the current state of the field, maps out future research directions and identifies challenges to progress. Highlighting more than 30 projects that represent important directions and approaches going forward, the article pulls together the building blocks for a toolkit with broader societal impact—such as smaller and more efficient technologies that clean water and air, monitor health and environmental quality, and make phones and electronic displays easier to read and harder to damage.

“A key point is mechanical robustness,” explains Ray. “If we’re extruding a material and it’s very fragile, or it cannot be patterned to connect to other materials effectively, it will likely not find its way into a device.”

“In a nutshell, we’re interested in understanding, from a composite-materials standpoint, how nanoparticles and the surrounding material can be integrated; not just to make interesting materials, but also to allow for patterning and integration into actual devices” Begley adds.

Despite the challenges, there is incredibly strong motivation for addressing these integration challenges. “The ability to make interesting nanoscale particles has simply exploded over the last decade; nanocrystals with different shapes, sizes and composition have created this incredible materials ‘palette’ to design entirely new types of functionality,” said Gianola.

This palette is just the first stage; nanoparticles must ultimately be arranged in useful ways at larger length scales. The authors illustrated that the coupling between stimuli and response is strongly enhanced by deterministic control of multiple length scales in a hierarchical structure.

The Science review outlines that the challenge of using ordered nanocomposites in applications stems from several related factors: “(i) limited pathways to synthesize and pattern such materials over length scales required for devices, (ii) fabrication techniques amenable to the integration of nanocomposites with other materials required to connect or protect functional components, and (iii) limited understanding of the thermomechanical stability of nanocomposites, both as isolated materials and as embedded components.”

Throughout the review, the authors highlight the critical roles of many different types of research, spanning scalable nanoparticle synthesis, self-assembly methods to bind particles together in organized patterns, acoustic assembly to organize particle aggregates, and 3D printing of nanocomposites to facilitate patterning in actual devices.

By integrating many different materials and device perspectives, the review provides keen insight regarding research that will lead to more widespread use of nanocomposites. “Our hope is that by taking a holistic view, we can help to identify sticking points for technology development,” says Gianola.

“Doing this allows us to more quickly identify material systems that exhibit both desirable properties and clear pathways to device integration. We are optimistic the review will, at the very least, stimulate many interesting discussions amongst our colleagues – that’s always the first step to inspiring advances.””