“Computerized design reveals how honeycomb-like frameworks with unusual rippled shapes can produce buckle-resistant architectures

Composite panels that sandwich a porous inner core between two solid outer sheets are increasingly being used in aircraft to reduce weight while maintaining structural rigidity. A study led by A*STAR may help other industries exploit the benefits of sandwich panels by using three-dimensional (3D) printing to generate core structures optimized for different mechanical loads.1

Many existing sandwich panels have cores inspired by the efficiently packed hexagonal cells inside beehives. Recently, researchers have investigated strategies to minimize the weights of cores by constructing lattice-like frameworks held together by thin beams known as trusses. But preventing these trusses from warping or buckling prematurely is still an ongoing challenge.

One surprising way that engineers are tackling this problem is by switching from normally straight trusses to ones with bumps, waves, and other irregular features. “Diameter variations allow for local thickening where the highest buckling moments occur, while reducing thickness in other areas along the trusses,” explains Stefanie Feih from the Singapore Institute of Manufacturing Technology (SIMTech) at A*STAR. “We can therefore keep the same mass, but increase the buckling strength significantly.”

In collaboration with researchers at the National University of Singapore (NUS) and the Hong Kong University of Science and Technology (HKUST), Feih and her co-workers developed a method to identify the strongest types of non-uniform trusses. They accomplished this by using mathematical techniques to characterize complex surfaces as simple variables — the smoothness of a surface, for example, or the frequency of a recurring shape. A computational algorithm then calculates the buckling strength of different geometric trusses, and suggests candidates based on the input design parameters.

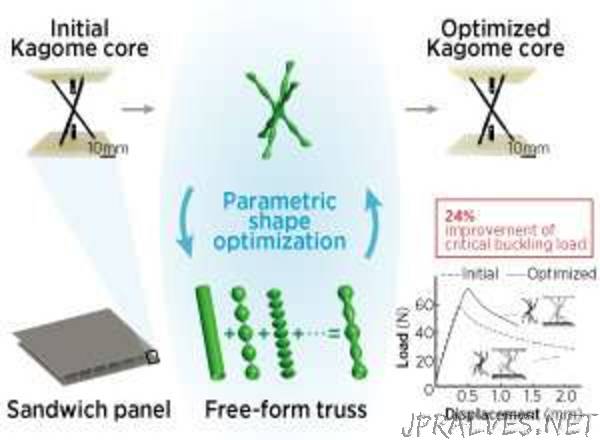

Lei Zhang, a PhD student at NUS who helped lead the study, notes that with just a few variables for optimization, this method can be easily scaled beyond simple one-dimensional shapes. To demonstrate this, the researchers modeled a 3D structure, known as a Kagome lattice, where star-shaped trusses have arms that extend in six different directions. Their simulations isolated a bumpy structure with 20 per cent better buckling resistance than uniform trusses of the same weight.

Because commercial fabrication technologies are geared toward producing uniform items, the team turned to additive manufacturing to generate a prototype sandwich panel from the optimally shaped Kagome lattice structure. The resulting 3D printed core validated the model’s predictions, setting the stage for future industrial applications.

“Current lattice structure designs are not taking full advantage of the possibilities of additive manufacturing,” says Feih. “Our work highlights the potential for tailored multi-functional designs, by combining, for example, mechanical and thermal requirements into one component.””