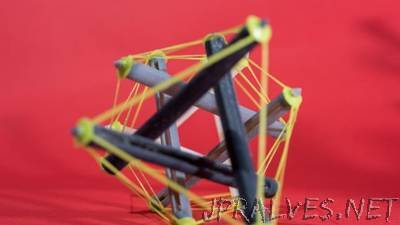

“A team of researchers from the Georgia Institute of Technology has developed a way to use 3-D printers to create objects capable of expanding dramatically that could someday be used in applications ranging from space missions to biomedical devices. The new objects use tensegrity, a structural system of floating rods in compression and cables in continuous tension. The researchers fabricated the struts from shape memory polymers that unfold when heated. “Tensegrity structures are extremely lightweight while also being very strong,” said Glaucio Paulino, a professor in Georgia Tech’s School of Civil and Environmental Engineering. “That’s the reason there’s a heavy amount of interest right now in researching the use of tensegrity structures for outer space exploration. The goal is to find a way to deploy a large object that initially takes up little space.” The research, which was reported June 14 in the journal Scientific Reports, was sponsored by the National Science Foundation and the Air Force Office of Scientific Research. The researchers used 3-D printers to create the struts that make up one of the primary components of the tensegrity structure. To enable the struts to be temporarily folded flat, the researchers designed them to be hollow with a narrow opening that runs the length of the tube. Each strut has an attachment point on each end to connect to a network of elastic cables, which are also made with 3-D printers. Once the struts were heated to 65 degrees Celsius, the researchers could partially flatten and fold them into a shape resembling the letter W. The cooled structures then retain the temporary shape. With all cables attached, the objects can be reheated to initiate the transformation into tensegrity structures.”