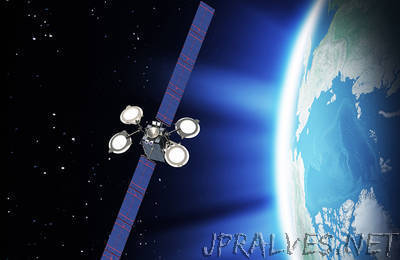

“Boeing is known for building huge, high-end satellites that cost roughly $150 million each, but that could change in the future. The aerospace corporation plans to adopt new production practices that involve the use of modular 3D-printed parts and far fewer workers than it’s used to, according to The Wall Street Journal. Its current procedures that require customized manual assembly cost too much and take far too long — apparently, you can count the number of satellites it builds in a year on two hands. Boeing’s satellite business chief Paul Rusnock told the WSJ that the company can’t continue what it’s been doing and remain competitive. Companies that maker smaller, cheaper satellites are already using modular components to save costs and pump out as many as possible. Airbus and a startup called OneWeb (a venture founded by Richard Branson’s Virgin and Qualcomm), for instance, are in the midst of building an automated assembly line in Florida. It’ll be capable of cranking out hundreds of small satellites a year that cost roughly $500,000 each.”