“Close communication between optics designers and manufacturers can help prevent problems

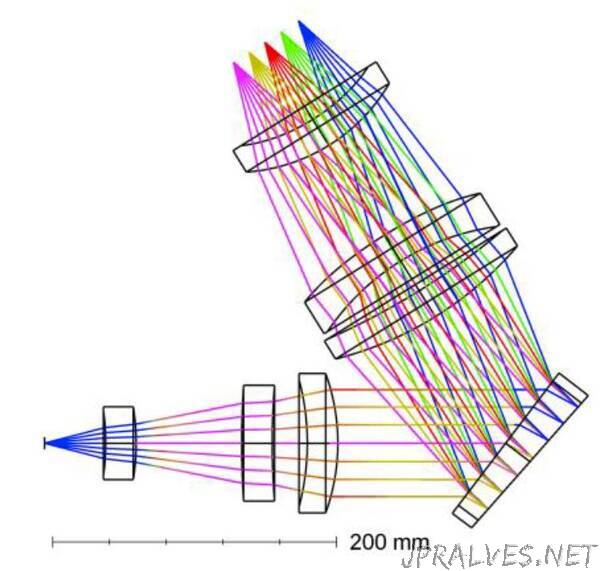

Although optical components such as lenses are traditionally spherical in shape, freeform optical components, which have little to no symmetry around the optical axis, are becoming more common. Freeform optical components are attractive because they can be designed to behave in ways traditional optics cannot, offering optical design flexibility not possible with traditional optics.

Michael Gregory from Optimax Systems Inc. will discuss important manufacturing and metrology considerations for freeform optics at the Optica Design and Fabrication Conference, which will take place 04 – 08 June 2023 in Quebec City, Canada.

Freeform optical surfaces play a pivotal role in a wide range of industries, offering numerous benefits. They allow for the creation of smaller and lighter telescopes without compromising performance or imaging resolution. Additionally, these surfaces can be effectively applied in fields such as lithography, directed energy, and laser communications. Freeform optical components can, for example, enable multiple optical aberrations, or errors, to be corrected with fewer optical surfaces, making the overall optical system smaller and lighter. However, this technology also presents unique challenges for designers and manufacturers.

During the talk, Gregory will outline several key manufacturing considerations. One of these includes the importance of understanding any manufacturing limitations early in the design process to ensure that the freeform optical surfaces are designed to be manufacturing friendly. For example, it’s critical to ensure that the freeform surface is well behaved outside the clear aperture.

It’s also key to consider the fact that freeform surfaces sometimes feature small areas of high curvature. Ideally, the local radius of curvature will be limited to 12 mm so that standard grinding and polishing tools can be used to fabricate the optical surface. Smaller tools create more mid-spatial frequency errors, which can affect the end performance.

Gregory will also discuss the importance of understanding a vendor’s plan for measuring freeform surfaces. Being knowledgeable about any metrology limitations is helpful for predicting the final performance.

The main point of the talk is to engage the manufacturing vendor as early in the process as possible. Designing and fabricating freeform surfaces presents a multitude of challenges. Early manufacturing feedback to the designer can help avoid late design iterations that eat into the manufacturing schedules. The designer may also use the manufacturing and metrology feedback to create a more robust and realistic tolerance analysis. This collaborative relationship can also help the vendor learn what is needed from the designer and new capabilities and techniques that need to be created. This will help develop the community’s knowledge of the specific challenges that require solutions. Although it can be challenging to design and fabricate freeform surfaces, interfacing with the optics vendor early in the process can help minimize fabrication and metrology pitfalls. This interaction also helps the vendor understand whether any new capabilities or techniques need to be created to meet the designer’s needs.”