“A new design for thermal actuators can create rapid movements in soft robotic devices.

Developed at North Carolina State University, potential applications for the fast-moving parts could include prosthetic devices and high-end manufacturing machines.

Actuators create motion by converting energy into work. “Using thermal actuation is not new for soft robots, but the biggest challenge for soft thermal actuators was that they were relatively slow – and we’ve made them fast,” said Professor Yong Zhu, corresponding author of the new research.

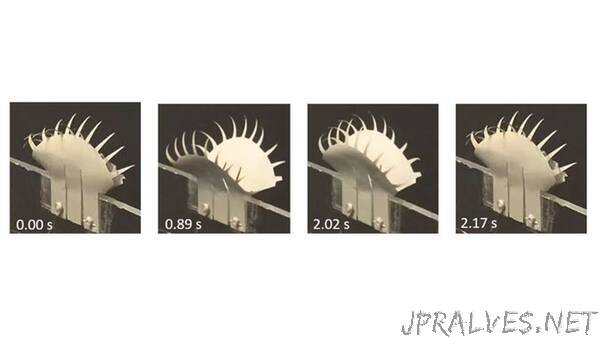

“What makes this new actuator design work is a structure with a bi-stable design,” said first author Shuang Wu. “Think of a snap hair clip. It’s stable until you apply a certain amount of energy (by bending it over), and then it snaps into a different shape – which is also stable.”

In the case of the new thermal actuator, the material is bi-stable and the shape it ‘prefers’ is dictated by temperature.

To create the new actuator, the researchers layered two materials with different coefficients of thermal expansion on top of each other, with silver nanowires in the middle. The layered materials were then shaped into a design with a default curvature in one direction.

When voltage is applied to the silver nanowires, the material heats up, making it bend in the other direction. Once the critical temperature is reached, the material snaps into its new default shape. When it cools down, the material snaps back to its previous default shape.

One prototype emulates the snapping behaviour of a Venus flytrap, while the other is a crawling robot, capable of moving more than one body length per second.

The team’s next steps include developing sensor and control mechanisms that could make the actuation process more automated.

“We’re also interested in exploring other possible materials, so that we could fine-tune the thermal and mechanical properties,” Zhu said. “This could allow us to tailor both actuator speed and force.”

The research was published in Soft Robotics. “