“Magnetic cable project will extend the reach of CERN’s high-energy physics collider

The U.S. Department of Energy’s (DOE) Lawrence Berkeley National Laboratory (Berkeley Lab) has passed the halfway mark in the multi-year process of fabricating crucial superconducting cables as part of a project to upgrade the Large Hadron Collider (LHC) at CERN. This upgrade, now in progress, will greatly increase the facility’s collision rate and its scientific productivity.

The High-Luminosity LHC Accelerator Upgrade Project, or HL-LHC AUP, is a multi-institutional, U.S. contribution to the upgrade of the LHC facility. The project is headquartered at DOE’s Fermi National Accelerator Laboratory (Fermilab).

A group of much more powerful focusing magnets, known as the “inner triplet,” are planned to be installed on either side of the LHC’s interaction points, where the separate proton beams collide. By squeezing the beams to higher density at the interaction points, these stronger focusing magnets will increase the number of collisions over the lifetime of the machine by at least a factor of 10. This will significantly enhance the opportunities for discovering new physics.

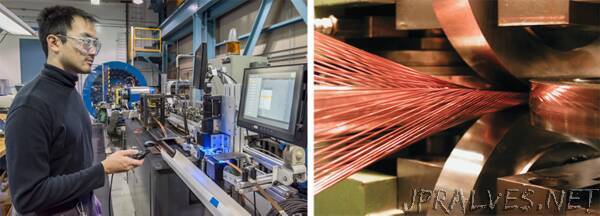

The coils for the HL-LHC AUP focusing magnets are made from advanced niobium-tin (Nb3Sn) superconductor in a copper matrix. One of Berkeley Lab’s key contributions is fabricating all the cables to be used in the magnets. The task reached the halfway mark in January 2021.

Fermilab’s Giorgio Apollinari, AUP Project Manager, said of the milestone, “This is a great ‘turning-of-the-buoy’ achievement since it allows the project to continue unimpeded in the production of these critical HL-LHC AUP magnets.”

Berkeley Lab project lead and Berkeley Center for Magnet Technology (BCMT) Director Soren Prestemon added, “This halfway mark is a tremendous milestone for our cabling team, who have delivered exceptionally for the project – even more remarkable given the complexities of on-site work under COVID constraints.”

The overall AUP was recently granted Critical Decision 3 (CD-3) approval in the DOE’s project-management process, giving the go-ahead for series production of the magnets themselves. Cable fabrication had already begun under a management approach in which long-lead-time items, such as wire procurement and cable fabrication, received approvals to go ahead before the series production of the magnets.

“The AUP project leverages extensive expertise and capabilities in advanced Nb3Sn magnet technology at Berkeley Lab,” said Cameron Geddes, director of Berkeley Lab’s Accelerator Technology and Applied Physics (ATAP) Division. ATAP and the Engineering Division formed the BCMT to join forces in advanced magnet design. Geddes added, “This critical milestone demonstrates the Lab’s commitment to the project and the team’s unique ability to deliver on its challenging requirements.”

From conductor to cable to magnet

Most people have seen or even built electromagnets made from coils of individual wire, a familiar item at school science fairs and in consumer products. However, there are many reasons why these would not work well in accelerator magnets. Instead, accelerators use cables formed from multiple strands of superconducting wire. The cables are flat, with a rectangular or very slightly trapezoidal “keystoned” cross section, a profile known as “Rutherford style” after the Rutherford Appleton Laboratory in England, which developed the design.

Rutherford cables are flexible when bent on their broad face, which makes coil winding easy. However, the strands at the thin edges of the cable are heavily deformed and their thermoelectric stability could be degraded, so the shaping must be carefully monitored and controlled.

The overall AUP team is supported by the DOE Office of Science and consists of six U.S. laboratories and two universities: Fermilab, Brookhaven National Laboratory, Lawrence Berkeley National Laboratory, SLAC National Accelerator Laboratory, and Thomas Jefferson National Accelerator Facility (all DOE national laboratories), along with the National High Magnetic Field Laboratory, Old Dominion University, and Florida State University. Each brings unique strengths to the challenges of designing, building, and testing these advanced magnets and their components. Industrial partners supply the superconducting wire.

Berkeley Lab ships the cables to Fermilab or Brookhaven to be fabricated into coils and reacted (heat treated) to activate their superconductivity. The reacted coils are returned to Berkeley Lab, which uses them to make quadrupole magnets. This recent article gives an in-depth look at how multiple institutions use their complementary strengths to make magnets for the AUP.

“These magnets are a culmination of more than 15 years of technology development, starting with the LARP (LHC Accelerator Research Program) collaboration,” said Dan Cheng of Berkeley Lab’s Engineering Division.

‘Eagle eyes for quality and big collaborative hearts’

Berkeley Lab, which celebrates its 90th anniversary this year, has a long history of national and international collaboration in designing and building accelerators, and its superconducting-magnet expertise goes back to the early 1970s.

The planetary-motion cabling machine at Berkeley Lab was designed and installed in the early 1980s and has received continual upgrades over the years. It has contributed to a large number of DOE projects such as the Fermilab Tevatron upgrade and then the early development of the Superconducting Super Collider. Today, the cabling facility is key infrastructure for Berkeley Lab’s superconducting-magnet activities.

The cabling facility also boasts a world-class suite of quality-assurance systems to monitor cable properties. These include an in-line cable measurement machine that can measure a cable’s dimensional parameters at a set pressure, an in-line camera system that can record every millimeter of all four sides of the fabricated cables and perform image analysis, and a specially designed cryo-cooler system for reproducibly measuring key parameters.

The people who assemble and use this equipment are in Berkeley Lab’s ATAP and Engineering divisions. Ian Pong, a staff scientist in ATAP and Berkeley Lab cabling manager for the HL-LHC AUP, said “We have not only world-class equipment for fabricating state-of-the-art superconducting cables, but most importantly, a world-class team of people who have eagle eyes for quality and big collaborative hearts for projects.”

Apollinari said, “The Berkeley Lab group led by Ian has been outstanding in the high-quality production of the Nb3Sn cables, meeting not only the demanding quality assurance and control requirements but achieving a production yield very much above and beyond the expected yield for this kind of activities. This is obviously of great help for the AUP Project, both economically and from the schedule point of view.””