“New partnership aims to bring a viable, zero-emissions product for heavy-duty vehicles to market

The U.S. transportation industry is the nation’s largest generator of greenhouse gases, accounting for nearly one-third of climate-warming emissions. To move towards a clean-energy future, developing zero-emissions technologies for heavy-duty vehicles is critical. A new partnership comprising Los Alamos National Laboratory, Advent Technology Holdings Inc., Brookhaven National Laboratory, and the National Renewable Energy Laboratory (NREL) will work over the next few years to bring to market high-temperature proton exchange membrane (HT-PEM) fuel cells that convert hydrogen and other renewable fuels into electricity.

“As the heavy-duty transportation industry seeks greener alternatives to combustion engines, HT-PEM fuel cells promise a clean, efficient alternative,” said Rod Borup, Los Alamos program manager for Fuel Cells and Vehicle Technology. Traditional PEM fuel cells have a relatively low operating temperature, which makes for a low tolerance to hydrogen fuel impurities and makes waste-heat rejection a challenge for vehicles. “This project hopes to change that, as well as contribute to the acceleration of energy and heavy-duty transportation technologies that will enable a clean, zero-emissions energy future,” said Borup.

HT-PEM fuel cells have potential to revolutionize the heavy-duty transportation industry. They can allow ships to run on renewable methanol or ammonia, airplanes to run on dimethyl ether or hydrogen, and off-grid power generators to work with low- or zero-carbon fuels that are easily transportable to remote locations. The ability to use any hydrogen-carrying fuel, in addition to pure hydrogen, is a major breakthrough in reducing the required infrastructure investments. HT-PEM fuel cell technology will allow heavy-duty and other hard-to-decarbonize applications to operate with high efficiency while using hydrogen and mitigating water management problems.

The project received strong funding support from the Department of Energy’s (DOE’s) Hydrogen and Fuel Cell Technologies Office through the L’Innovator (“Lab Innovator”) Pilot Program, which is designed to address specific challenges associated with the transition of hydrogen and fuel cell technologies from DOE’s national laboratories into the commercial marketplace. Breakthroughs coming out of this effort will help to enable DOE’s H2@Scale vision for clean and affordable hydrogen utilization across multiple sectors in the economy.

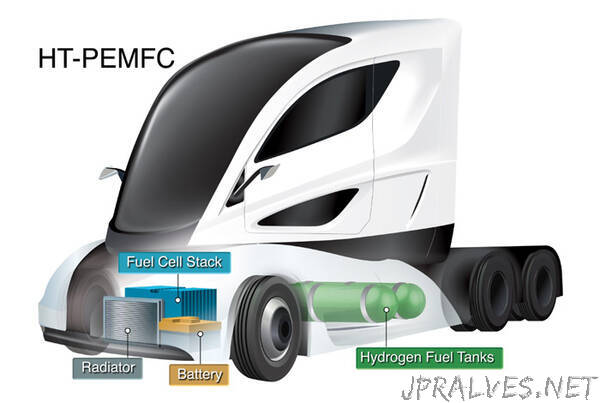

Los Alamos’ contribution to the project is the membrane electrode assembly (MEA). The MEA is unique because it doesn’t rely on water as the conducting medium, but on an engineered polymer, which allows for a wider range of high temperatures for reliable operation (80oC to 200oC). “At high-temperature operation, we can build heavy-duty trucks with a much simpler design, which allows us to significantly reduce the weight,” said Yu Seung Kim, a Los Alamos scientist who started this automotive HT-PEM fuel cells project at the Laboratory in 2017. “The heaviest part of the typical hydrogen fuel-cell system is the hydrogen storage tanks that weigh about 4,000 pounds to haul for a distance of 350 miles. If you run fuel cells at a higher operating temperature, you can use high-energy-density liquid fuels and the system weight can be reduced to 2,500 pounds.”

The partnership formalizes each party’s role and the next steps to creating a viable product. Kim’s team at Los Alamos will be responsible for demonstrating MEA performance and durability using screening tests of membrane, ionomer, catalyst, and gas diffusion layers. The resulting knowledge will be transferred to NREL to help develop the manufacturing process for mass production of MEAs. Brookhaven Lab is responsible for developing oxygen reduction reaction catalysts, while Advent will test and validate that performance and durability are maintained during industrial manufacturing conditions and will assemble the full-scale MEAs into a commercially viable fuel cell stack.”