“Researchers from St Petersburg University have developed the NeuroPrint soft neuroprosthesis 3D printing technology. In the long term, this can help paralyzed people after spinal cord injury. The new development has already shown its effectiveness in studies on mammals and zebrafish. The results are published in Nature Biomedical Engineering.

According to the World Health Organization, more than a billion people, that is, about 15% of the world’s population, have various forms of disability. Every year, up to half a million people receive spinal cord injuries, which are often accompanied by paralysis, and disorders of autonomic functions. To find ways to restore health to people with disabilities, researchers are developing invasive neuroprostheses that can transmit electrical signals to the spinal cord and brain and recover lost functions.

One of the main challenges faced by doctors and scientists is the adjustment of neuroprostheses to the surrounding nerve tissues of a person. Despite the biocompatible elastic materials, it is not always possible to adapt quickly the device to the anatomical and age characteristics of the patient. The solution to this problem has been proposed by a research team headed by Professor Pavel Musienko from the Institute of Translational Biomedicine at St Petersburg University and Professor Ivan Minev from the University of Sheffield (the Department of Automatic Control and Systems Engineering, the University of Sheffield). They have developed a new 3D printing technology that makes it possible to rapidly customise muscular and neural implants for monitoring and restoring of motor and autonomic functions.

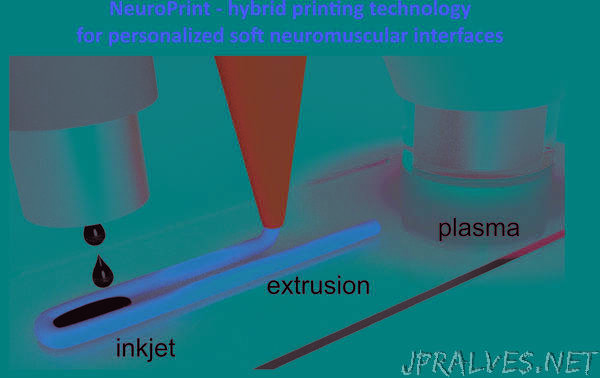

This patient-specific approach is now possible thanks to NeuroPrint hybrid 3D printing technology. First, the printer creates the geometry of the future implant made of silicone, which also serves as an insulating material. Then microparticles of platinum or another electrically conductive element of the implant are applied to the framework. Then the surface is activated by cold plasma. Moreover, the number and configuration of electrodes in the neural implant can be changed, producing devices for implantation in the tissue of the spinal cord, brain or muscles. The average production time from project creation to prototyping can be just 24 hours.

‘By the developed technology, the process of creating implants can become a lot faster and cheaper,’ said Professor Pavel Musienko, Head of the Laboratory of Neuroprosthetics at the Institute of Translational Biomedicine, St Petersburg University. ‘Considering the compactness of the equipment and the versatility of the approach, it is quite likely that in the future it will be possible to produce patient-specific neural implants right in the hospital. This follows the principles of personalized medicine and will minimise the cost and delivery time as much as possible.’

Neuroscientists have already exploited the NeuroPrint technology to carry out research on various model objects — mammals and zebrafish. It has shown that the new neural implants have a high level of biointegration and functional stability. Also, they are as good as their counterparts when they are used to restore motor functions of the limbs and monitor the bladder activity. Additionally, the scientists have been able to print soft implants similar in shape and mechanical characteristics to the dura mater — outer connective tissue membrane of the brain. This is an important achievement, since many scientific experiments cannot be carried out due to too rigid neuronal implants that are not suitable for the soft structures of the nervous tissue. Moreover, this limits their use in clinical practice.

‘We have tested our development in experiments on freely moving rats for chronic recording of the electrocortical signals of the cerebral cortex, that is a necessary element of the brain-computer interface,’ said Pavel Musienko. ‘The experiments on paralysed animals have shown that electrical stimulation of neural networks effectively restores locomotor function. Thus, the NeuroPrint technology opens up new opportunities both for basic research into the central nervous system and for neuroprosthetics when people suffer from various diseases and injuries.’

Among the participants of the research are scientists from: St Petersburg University; Pavlov Institute of Physiology of the Russian Academy of Sciences; Granov Russian Research Centre of Radiology and Surgical Technologies; St Petersburg State Research Institute of Phthisiopulmonology of the Ministry of Health of the Russian Federation; Ural Federal University; Technische Universität Dresden (Germany); and the University of Sheffield (the UK).

For reference:

The research has been supported by grants from: St Petersburg University; European Research Council; Technische Universität Dresden; the Russian Foundation for Basic Research; the German Research Foundation (the Deutsche Forschungsgemeinschaft); and Volkswagen Foundation.”