“In Situ Vapor-Deposited Parylene Substrates for Ultra-thin, Lightweight Solar Cells

Nearly all modern solar panels have one thing in common: glass. A 3-millimeter-thick glass sheet protects and supports the solar cells beneath it, but also contributes up to 90% of the panel’s total weight. That heft adds to the cost of transporting and installing solar PV systems, which today makes up a large part of the cost of solar electricity. Rigid and heavy cells also limit the potential for solar cells to power lightweight mobile devices and other applications. Flexible plastic films have been studied as alternatives to glass substrates for solar cells for years. Examples include variants of polyethylene terephthalate (PET)—used in soda bottles and plastic wrap—and polyethylene naphthalate (PEN)—used in beer bottles and sailcloth. But these plastics are typically flattened mechanically (“top-down”) into sheets and are thus difficult to make extremely thin (~1 micron thick) and uniform; they also require extra cleaning steps before solar cells can be fabricated on them.

In this project, we are using ultrathin films of a transparent polymer known as parylene as alternative substrates for lightweight, flexible solar cells. Parylene is a commercially available plastic coating used widely to protect implanted biomedical devices and printed circuit boards from environmental damage. Transparent, clean (contaminant-free) parylene films can be formed by “bottom-up” chemical vapor deposition (CVD) on nearly any solid surface with precise thickness control. No extra cleaning steps are required.

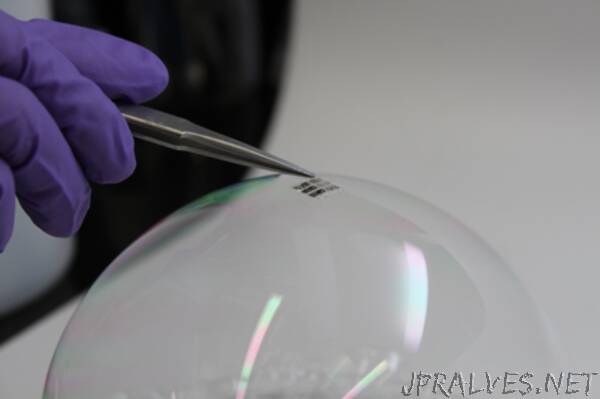

We deposit a thin (~1 micron) layer of parylene on glass, fabricate thin-film solar cells on the parylene, then peel the entire structure off the glass—parylene and all. The resulting devices are the thinnest complete solar cells demonstrated—less than 0.05% of the thickness of equivalent devices on glass substrates—yet they convert sunlight into electricity as efficiently as their rigid counterparts, with a specific power (power-to-weight ratio) of 6 W/g or higher—among the highest achieved with any PV technology. With further development, parylene and other flexible polymer substrates could open the door to new form factors and new applications for solar photovoltaics.”