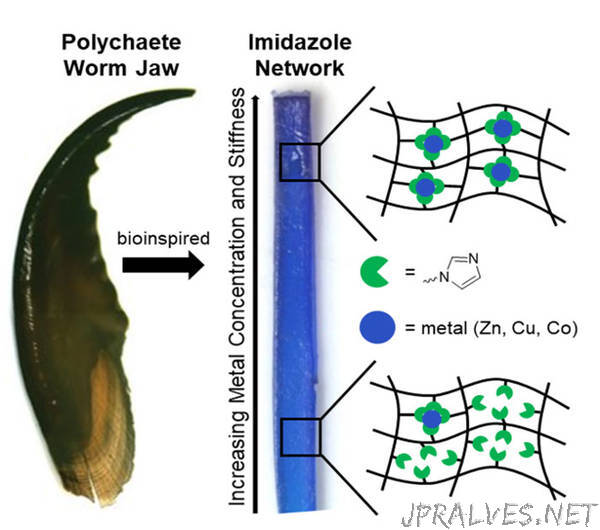

“Known as the polychaete worm, it uses the tip of its jaw to inject lethal venom. The design of the jaw, with a gradient of hard materials at the tip connected to softer tissues, dissipates force and prevents serious damage to the jaw. The gradient in mechanical properties is correlated to the number of metal ions available for bonding. This mechanism inspired a novel approach to generate stiffness gradients in human-made polymers. Through a simple process, scientists controlled the density of the metal ions along a sample. The gradient in metal ion interactions created a continuous gradient in mechanical properties that spanned over a 200-fold change in stiffness, approaching that of biology.

The Impact

Mechanical gradients (that is, from hard to soft) can prevent damage from large forces. It’s difficult to design materials with large gradients. The sample has the largest continuous span in human-made materials to date. Because the material is made using ordinary lab equipment, it could be made widely available for a broad range of uses. Such materials may find use as more resilient parts in vehicles, batteries, and power production devices. Further, the findings address long-standing issues in the design and formation of resilient polymer materials.

Summary

Mechanical gradients are often employed in nature to prevent damage from large forces by creating a smooth transition from strong to weak biological materials. This process enables living organisms to withstand tremendous forces. The incurred stress is dissipated as it is transferred from hard exterior appendages to weaker, easily damaged, interior soft tissues. Synthetic mimics of these natural structures are highly desired to improve distribution of stresses at interfaces and reduce contact deformation in human-made materials. Current synthetic gradient materials commonly suffer from non-continuous transitions, relatively small gradients in mechanical properties, and difficult syntheses.

Scientists at the University of California-Irvine have addressed both the design and synthetic challenges by taking inspiration from the polychaete worm. The worm creates a mechanical gradient that prevents damage to its jaw during biting and venom injection. The worm’s jaw employs a system of an increasing number of crosslinks between metal ions and proteins able to selectively bind to those ions. In the new human-made material, zinc, copper, or cobalt ions interact in a dynamic, non-permanent way with motifs that mimic the protein chemistry. The binding ligands are covalently attached to polymers and derived from nitrogen-based moieties (imidazoles). The extent to which a specific region is stiff or soft depends on the density of metal ions—a higher density produces a stiffer material. Varying this density over the length of the material generates a range of mechanical properties much like that present in the worm’s jaw.

This metal ion gradient was created using a very simple process. A polymer was attached to a device that slowly raised the polymer out of a metal salt solution. At the same time, additional metal solution was injected into the original solution. This combination along with the dynamic metal-ligand interactions is what enabled the continuous metal ion gradient to be formed along the length of the polymeric material. The highest stiffness occurred at the end that remained the longest in the metal solution and gradually decreased in a manner that correlated well with exposure to the salt solution. The largest and most well-defined gradient span displayed a 230-fold increase in stiffness. The magnitude of this range closely resembles that seen in squid beaks, which is a standard for many gradient materials.

The correlation between metal concentration and mechanical gradients indicates that the metal-imidazole interactions increase resiliency. This simple approach could be generalized to create a variety of materials.”