“In our everyday lives, pressure can mean a looming work deadline, a final exam, or bases loaded in the bottom of the ninth. In scientific terms, pressure is a physical quantity that’s important for many things, including car tires, blood circulation and breathing, semiconductor manufacturing of high-speed computer chips, and the weather.

Accurately measuring pressure for important applications currently requires a large device in a lab. But the National Institute of Standards and Technology (NIST) is aiming to move a promising new laser-based pressure-measurement technique it invented into the larger world, potentially reducing the costs for everything from airplane flights to chip manufacturing. NIST and MKS Instruments, Inc., of Andover, Massachusetts, have signed a collaborative agreement to make the technique more portable and transportable so that it could be developed into a commercial product.

Better measurements of pressure will have many applications, said NIST physicist Jay Hendricks, the leader of the project. For example, the Federal Aviation Administration worked with industry to safely reduce the vertical distance between nearby airplanes (link is external) to 1,000 feet, and further reductions are possible. Since the air pressure surrounding an aircraft changes with altitude, a more precise pressure sensor could help make this happen, Hendricks said.

“In the future, this could lead to savings in fuel costs,” he said. With reduced vertical separation, flight controllers could safely arrange planes more densely, enabling both fuel savings and more frequent on-time landings.

In manufacturing semiconductor chips, such as those in smartphones, Hendricks said, engineers must adjust the pressure of the gas environments in which the chips are made. Conventional pressure sensors, known as capacitance diaphragm gauges, are precise, but their readings must be kept within tight values, requiring engineers to adjust the sensors on a regular basis. More stable and accurate measurements of pressure could make semiconductor yields more reliable and less prone to defects, reducing costs for manufacturers and consumers.

In defense applications, aircraft such as the Apache helicopter must fly low to survey terrain. Such aircraft rely on pressure sensors to ensure they are flying safely. But “on any one day a sensor might be throwing a fit,” Hendricks said, and the airplane could be grounded until the problem is found. “If you could make a portable, handheld, NIST-traceable standard that you can use in the field, you could reduce downtime,” he said.

Standard pressure-measurement devices have limitations that limit performance in these applications. So, NIST set out to make a state-of-the-art sensor that could improve performance while providing fundamental measurements of pressure.

To measure the pascal, the SI unit of pressure, the scientific community has traditionally relied on a tall, bulky device known as a mercury manometer. Elemental mercury, which is a hazardous neurotoxin, adjusts its height in response to changes in pressure. “We’ve been using mercury manometers for almost 375 years, and they’ve served us well,” said Hendricks. “They were state of the art in their day. But about five years ago, we realized that there’s got to be a better way to do this.”

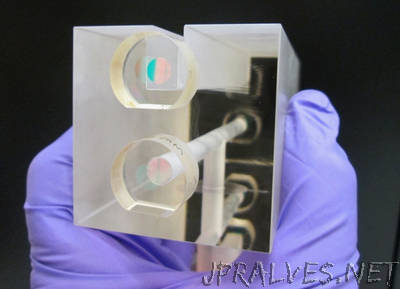

The result is called the FLOC—the fixed-length optical cavity. It’s a rectangular slab of translucent material, known as ultra-low expansion (ULE) glass, that you can hold in your hand. It contains two thin tubes or “cavities” through which laser light can travel. Besides being 20 times smaller in size and mercury-free, the FLOC’s higher resolution also enables it to measure pressure changes that are 36 times smaller than the traditional mercury standard. In principle, the device can measure any gas at low pressure, such as the gas in a semiconductor fabrication facility, to high pressures, such as on the sea floor. Presently, different kinds of pressure sensors are required to cover the same range.”