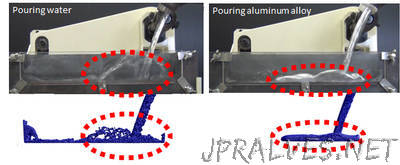

“Fujitsu Limited and Daido University Professor Yasuhiro Maeda have jointly developed new simulation technology that can accurately replicate splash and wave behavior in the surface of molten metals when they are being poured. In the casting process, which is used in component manufacturing in a variety of fields, such as automobiles and IT devices, molten metal is poured into a mold to be cast into a shape. The way molten metal flows through the interior of a mold significantly effects casting quality, but because the interior is impossible to see, there has been a demand for a simulation that can clarify how molten metal flows within the mold. However, simulation of this flow has been difficult to achieve as the way molten metal flows can change greatly depending on the oxide film that forms when metal contacts the air. Now, based on a simulation technology known as the particle method(1), Fujitsu and Daido University have developed a new way to calculate flow variations with physical properties (viscosity) near the boundary between it and the air. This technology was then verified, comparing it to an actual experiment modeling a process where aluminum alloy melted at high temperatures is poured into casting equipment, which confirmed that the manner of splash suppression in line with the oxide film on the poured liquid metal could be accurately simulated. This technology creates a simulation to clarify how molten metal flows inside casting equipment and molds, a process which cannot be observed from the outside. This will make it possible to change metal pouring procedures so as to more quickly manufacture high quality products, which is expected to contribute to improving casting productivity. Details of this technology will be announced at the 169th JFS Meeting (Japan Foundry Engineering Society), which will be held on the Setagaya campus of Tokyo City University on May 26-29.”