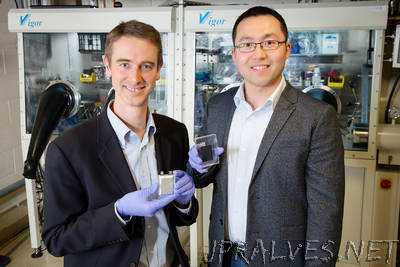

“The process that makes gold-plated jewelry or chrome car accents is now making powerful lithium-ion batteries. Researchers at the University of Illinois, Xerion Advanced Battery Corporation and Nanjing University in China developed a method for electroplating lithium-ion battery cathodes, yielding high-quality, high-performance battery materials that could also open the door to flexible and solid-state batteries. “This is an entirely new approach to manufacturing battery cathodes, which resulted in batteries with previously unobtainable forms and functionalities,” said Paul V. Braun, a professor of materials science and engineering and director of the Frederick Seitz Materials Research Lab at Illinois. He co-led the research group that published its findings in the journal Science Advances. Traditional lithium-ion battery cathodes use lithium-containing powders formed at high temperatures. The powder is mixed with gluelike binders and other additives into a slurry, which is spread on a thin sheet of aluminum foil and dried. The slurry layer needs to be thin, so the batteries are limited in how much energy they can store. The glue also limits performance.”