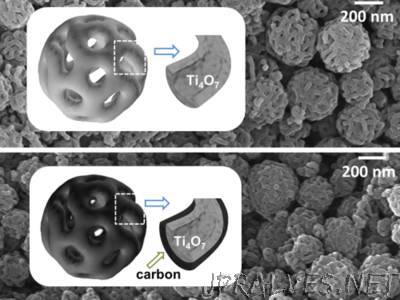

“A team at the Helmholtz-Zentrum Berlin (HZB) has for the first time fabricated a nanomaterial made from nanoparticles of a titanium oxide compound (Ti4O7) that is characterised by an extremely large surface area, and tested it as a cathode material in lithium-sulphur batteries. The highly porous nanomaterial possesses high storage capacity that remains nearly constant over many charging cycles. At present, lithium batteries are one of the best solutions for storing electrical power in a small space. Lithium ions in these batteries migrate from the anode to the opposite electrical pole, the cathode, during the discharge cycle. The anode and cathode generally consist of heavy-metal compounds that are expensive and toxic. One interesting alternative is the lithium-sulphur battery. In this case, the cathode does not consist of heavy metals, but instead of sulphur – an economical and widely available material. As lithium ions migrate to the cathode during the discharge cycle, a reaction takes place there that forms lithium sulphide (Li2S) via various intermediate lithium polysulfides. During cycling, dissolution of lithium polysulfides causes the battery’s capacity to decline over the course of multiple charging cycles via the so-called “shuttle effect”. For this reason, researchers the world over are working to improve cathode materials that would be able to chemically or physically confine or encapsulate polysulphides, such as with nanoparticles made of titanium dioxide (TiO2), for example.”