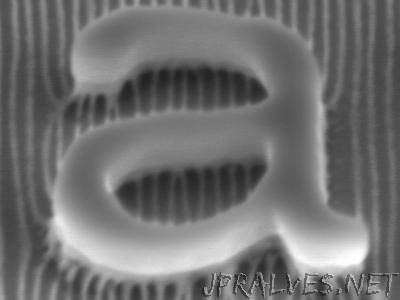

“For the chips in our computers and smartphones to get faster, their components—the circuits and wires through which signals flow—have to get smaller. The miniaturization of these wires has taken scientists on a journey almost to the atomic level. Recently, scientists have begun to address and surmount certain barriers in physics that have prevented them from making even smaller wires. In a recent study published in Nature Nanotechnology, a team of researchers from the Argonne National Laboratory, the University of Chicago and MIT has developed a new way to create some of the world’s thinnest wires, using a process that could enable mass manufacturing with standard types of equipment. Templated assembly, or directed self-assembly, represents an easier and more cost-effective way to make nanowires with widths below 10 nanometers, which is about 100 atoms thick. The self-assembling materials are large molecules known as block copolymers. These block copolymers are the two-headed beasts of the chemical world—one end is water-loving, the other end is water-hating. Upon heating, they spontaneously form highly uniform structures at the molecular scale. On their own, however, the block copolymers would form a pattern that looks like a fingerprint or a piece of brain coral—useless for the creation of functional nanowires. The key to changing that pattern to something more ordered is the use of the chemically patterned templates.”