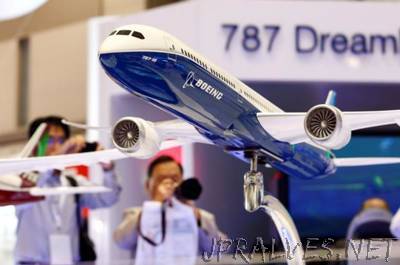

“Boeing Co hired Norsk Titanium AS to print the first structural titanium parts for its 787 Dreamliner, a shift that the Norwegian 3-D printing company said would eventually shave $2 million to $3 million off the cost of each plane. The contract announced on Monday is a major step in Boeing’s effort to boost the profitability of the 787 and a sign of growing industrial acceptance of the durability of 3-D printed metal parts, allowing them to replace pieces made with more expensive traditional manufacturing in demanding aerospace applications. Strong, lightweight titanium alloy is seven times more costly than aluminum, and accounts for about $17 million of the cost of a $265 million Dreamliner, industry sources say. Boeing has been trying to reduce titanium costs on the 787, which requires more of the metal than other models because of its carbon-fiber fuselage and wings. Titanium also is used extensively on Airbus Group SE’s rival A350 jet.”