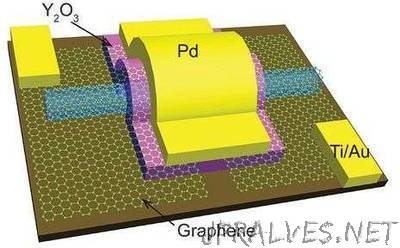

“A team of researchers at Peking University has built a carbon nanotube-based working transistor and report that it outperformed larger transistors made with silicon. In their paper published in the journal Science, the team describes how they built the transistor, how it performed and the challenges that still remain before such transistors can be mass produced. Everyone in the computer business knows the limit to which silicon-based transistors can be made smaller is drawing ever closer, so many teams around the world are searching for a suitable replacement. One of the most promising candidates is carbon nanotubes—due to their unique properties, transistors based on them could be smaller, faster and more efficient. Unfortunately, the difficulty in growing carbon nanotubes and their sometimes persnickety nature means that a way to make them and mass produce them has not been found. In this new effort, the researchers report on a method of creating carbon nanotube transistors that are suitable for testing, but not mass production. To create the transistors, the researchers took a novel approach—instead of growing carbon nanotubes that had certain desired properties, they grew some and put them randomly on a silicon surface and then added electronics that would work with the properties they had—clearly not a strategy that would work for mass production, but one that allowed for building a carbon nanotube transistor that could be tested to see if it would verify theories about its performance. Realizing there would still be scaling problems using traditional electrodes, the researchers built a new kind by etching very tiny sheets of graphene. The result was a very tiny transistor, the team reports, capable of moving more current than a standard CMOS transistor using just half of the normal amount of voltage. It was also faster due to a much shorter switch delay, courtesy of the intrinsic delay of just 70 femtoseconds.”