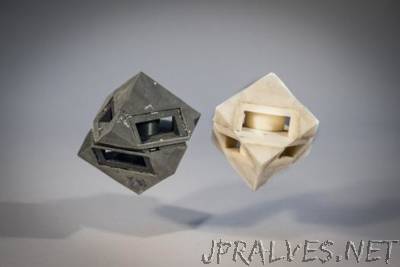

“Anyone who’s watched drone videos or an episode of “BattleBots” knows that robots can break — and often it’s because they don’t have the proper padding to protect themselves. But this week researchers at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) will present a new method for 3-D printing soft materials that make robots safer and more precise in their movements — and that could be used to improve the durability of drones, phones, shoes, helmets, and more. The team’s “programmable viscoelastic material” (PVM) technique allows users to program every single part of a 3D-printed object to the exact levels of stiffness and elasticity they want, depending on the task they need for it.”